SPC Monitoring:

Maintain Process

Stability

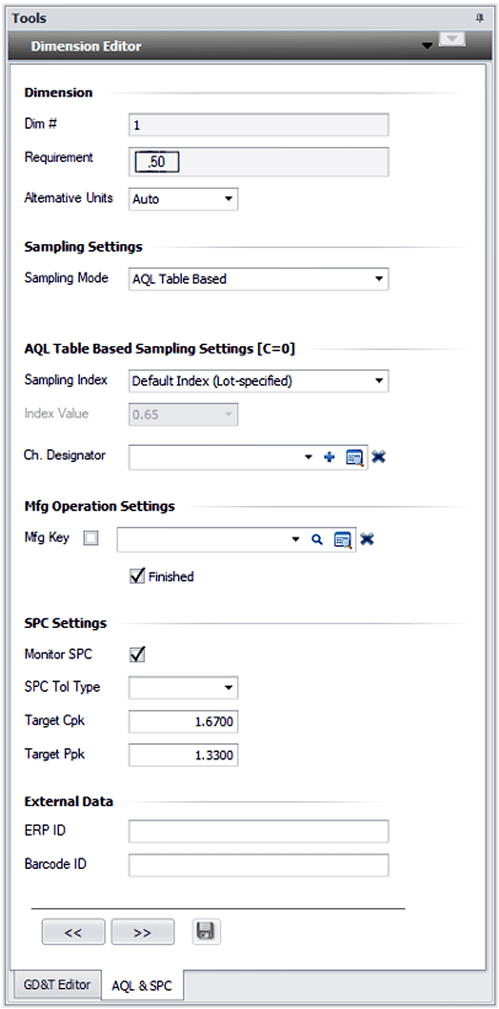

High QA’s Statistical Process Control (SPC) tool enables real-time monitoring of production processes, helping to ensure compliance and maintaining stability throughout the manufacturing process . Integrated into IM/ 360 CORE, SPC Monitoring provides actionable insights into process capabilities and performance metrics.

Overview

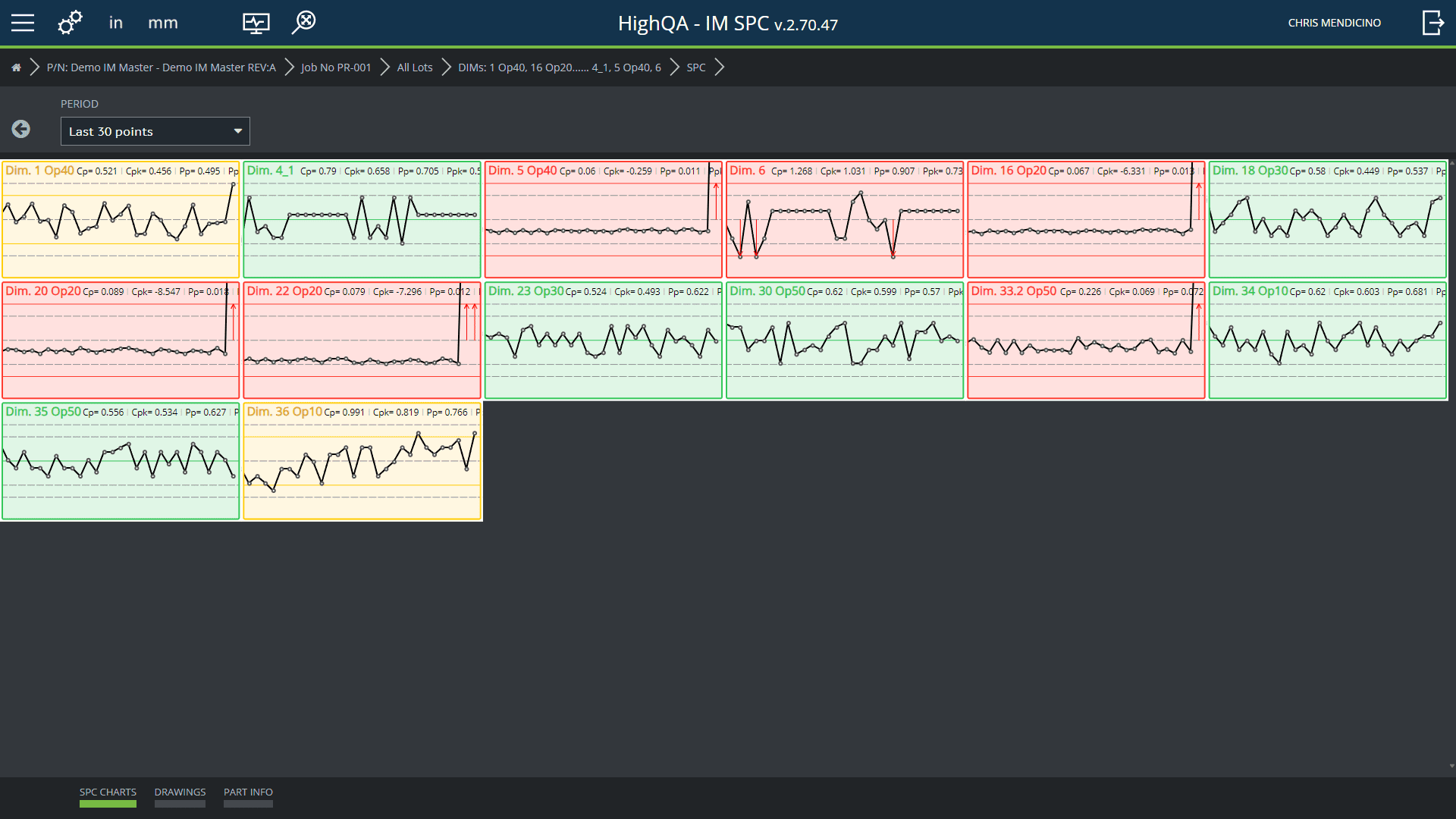

SPC Monitoring is a key tool for maintaining production consistency. High QA’s SPC features allow manufacturers to monitor critical dimensions and detect deviations in real time. By collecting data directly from CMMs, gages, and other systems, SPC Monitoring supports informed decision-making and helps to maintain Ppk and Cpk levels. Fully integrated with IM/ 360 CORE, this feature connects seamlessly with the BoC and other tools to provide a comprehensive view of process performance.

Key Benefits

Real-Time

Data

- Monitor critical dimensions and tolerances during production to help ensure immediate visibility into process stability.

Actionable

Insights

- Analyze process capability using metrics like Cpk and Ppk to make data-driven decisions.

Integrated

Workflows

- Link SPC data directly with the BoC and inspection plans for streamlined analysis and reporting.

Proactive Quality

Control

- Quickly identify and correct process deviations to maintain product excellence.

Discover More

Maintain process stability with HighQA’s SPC Monitoring feature. Discover how real-time data insights and process capability analysis can enhance quality control and decision-making. Schedule a demo today to see how SPC Monitoring can improve the consistency and quality of your production processes.