Operations &

Routings:

Streamline ProductionInspection Planning

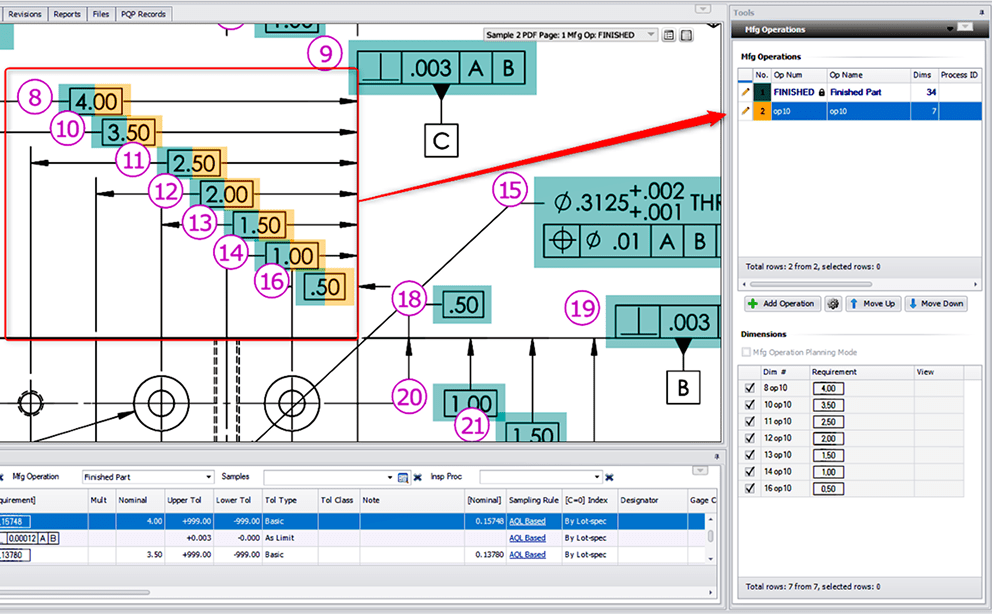

High QA’s Manufacturing Operations tool simplifies inspection planning by breaking down your production lifecycle into manageable stages. Integrated within IM/ 360 CORE, this feature enables you to define inspection requirements for each manufacturing step, from roughing to finishing, ensuring alignment with PpK Process standards and improving compliance during supplier audits.

Overview

Plan inspection requirements at every stage of production with Manufacturing Operations. This tool allows users to create tailored workflows for inspection steps like drilling, milling, and plating while connecting them to High QA’s IM/ 360 CORE system. Whether working with default settings or building custom operations, manufacturers can streamline workflows and ensure quality across every step of the production lifecycle.

Key Benefits

Tailored Inspection Plans

- Define inspection requirements for every step, including roughing, drilling, and finishing.

Custom Workflows

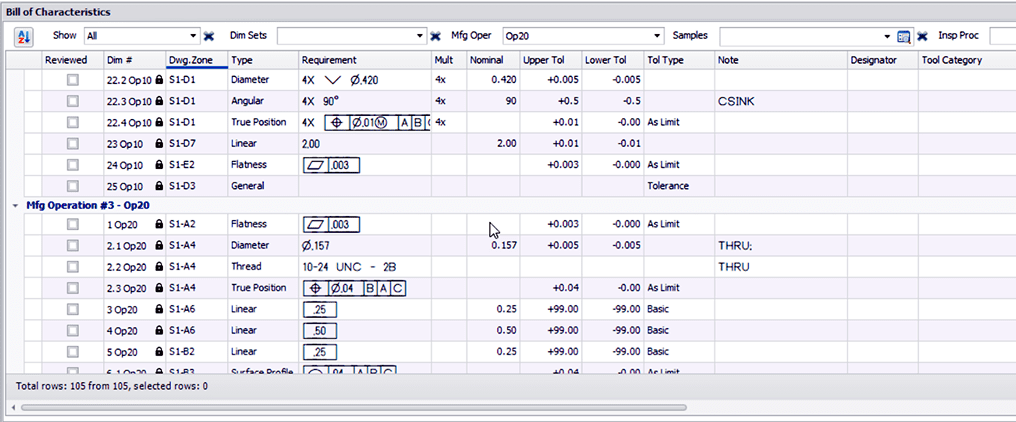

- Tailor operations to specific requirements with detailed parameters such as work cells, machine details, and process instructions.

Seamless Integration

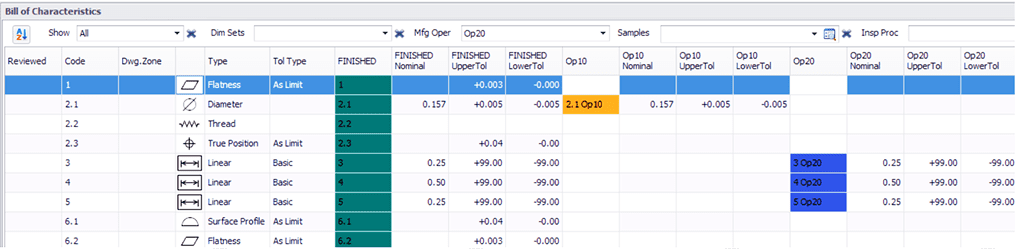

- Link operations directly to the Bill of Characteristics (BoC) and obtain a clear view of inspection requirements at every stage.

Enhanced Compliance

- Ensure alignment with PpK Process standards, making supplier audits more efficient and thorough.

Simplify the Process

High QA’s Manufacturing Operations tool makes it easy to:

- Add operational steps directly to parts and drawings.

- Assign dimensions to specific manufacturing steps, with color-coded visualizations for clarity.

- Create custom operation sheets and map dimensions between steps to maintain consistency.

Discover More

Optimize your production inspection planning with HighQA’s Manufacturing Operations tool. Learn how it integrates inspection requirements at every stage of the manufacturing lifecycle, improving compliance and efficiency. Schedule a demo today to see how this feature can enhance your production workflows.