Manufacturing Quality. Linked to Design.

One Platform from Design to Delivery

Connect your internal and supplier quality to the original 2D drawing or 3D model. From first inspection through final delivery — no delays, no rework, no surprises.

Deliver Every Part 100% On-Time,

On-Budget, & On-Quality

From internal quality to supplier performance, our platform helps manufacturers and OEMs eliminate escapes, lower cost of quality, and consistently hit delivery targets — without sacrificing standards.

Connect Quality Across Every Stage of Manufacturing

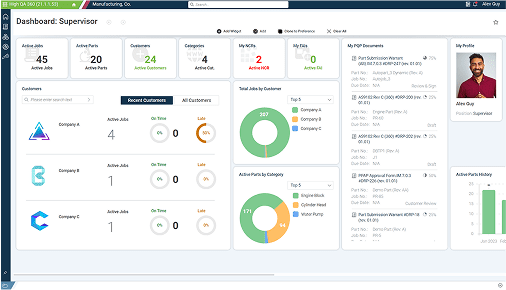

High QA unifies planning, inspection, reporting, and collaboration into a quality platform that keeps the original design at the center.

Interactive Quality Engagement

One System, One Database, One Interface

Eliminate

Interpretation

Real Time Data

and Analytics

Secured and Integrated with ERP

Eliminates

Bottlenecks

More

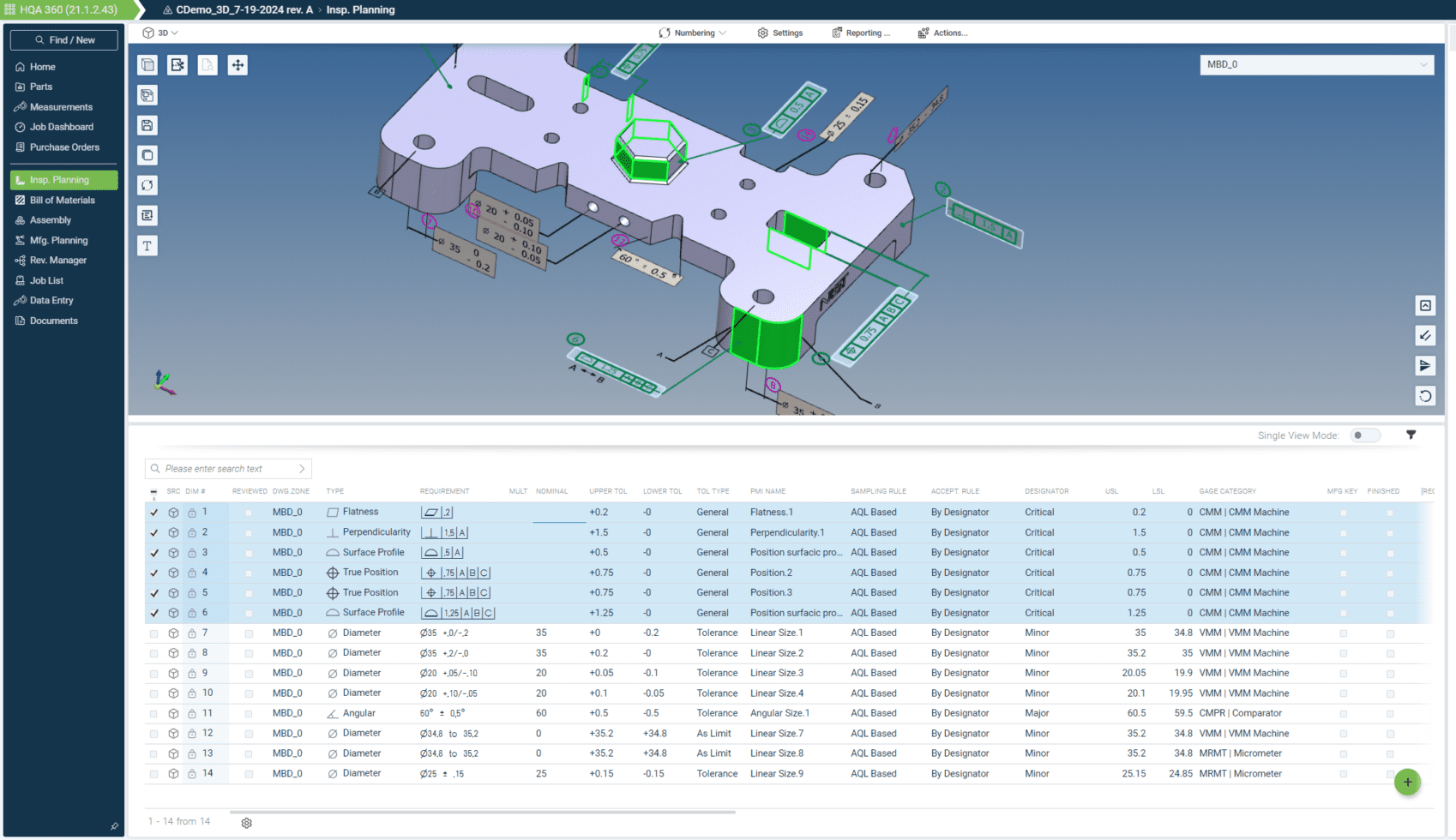

PARTS AND JOB PLANNING

Automatic 2D

& 3D Ballooning

3D-MBD

Integration

GD&T & PMI

Extraction

Operations &

Routings

PRODUCTION & DATA COLLECTION

CMM & Gage

Data Collection

NCR’s

& Defects

SPC

Monitoring

Tool & Gage

Management

REPORTING & SUBMISSIONS

Digital

Signatures

Digital

Workflows

PPAP/APQP

Management

First Article

Inspection

COLLABORATE WITH SUPPLIERS

Collaborative

Data Exchange

Part

Measurements

Supplier

FAI / PPAP

Supplier

Management

Quality That Scales Beyond Your Four Walls

Trusted by Leading Manufacturers & OEMs

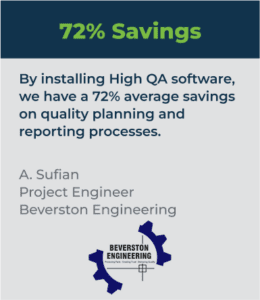

From Bottlenecks to Breakthroughs. Powered by a platform built for speed and scale.

Automate Your Manufacturing Quality. Cut Costs. Win More Work.

Give your team the tools to streamline quality, ensure compliance, and deliver without compromise.

- NEliminate incoming inspections with improved supplier collaboration

- NMeet regulatory standards with digital traceability and audit readiness

- NReduce scrap, rework, and delays using real-time quality data

- NDeliver consistent quality that keeps customers coming back

- NProve compliance upfront to win contracts and get paid faster