PPAP:

Streamline Production Approval with High QA

High QA supports the Production Part Approval Process (PPAP) by providing an integrated toolkit for managing and automating essential PPAP documents like Process Flows, PFMEA, and Control Plans. This centralized solution helps to ensure compliance, traceability, and efficiency for all your submission requirements, reducing the complexity of traditional PPAP workflows.

Overview

PPAP is a critical requirement for many manufacturers, especially in regulated industries like automotive and aerospace. High QA’s PPAP solution, part of the PQP (Production Quality Planning) module, simplifies the creation and management of essential PPAP documents while helping to ensure alignment with customer preferences and regulatory standards.

From generating ballooned drawings to building complete submission packages, High QA integrates tools for Process Flow Diagrams, PFMEA (Process Failure Modes and Effects Analysis), and Control Plans into a seamless workflow. By centralizing and automating document generation, manufacturers can streamline the approval process and focus on continuous improvement.

Key Benefits

Document

Management

- Keep all PPAP documents, including Process Flows and PFMEAs, on one accessible platform.

Automated

Workflows

- Link manufacturing operations directly to PPAP documents to minimize manual input and errors.

Compliance with

ISO/AS

- Meets ISO/AS and other industry standards with preloaded templates and built-in traceability.

Dynamic

Reporting

- Generate and customize PPAP documents like Control Plans and PFMEAs directly from manufacturing data.

Submission

Packages

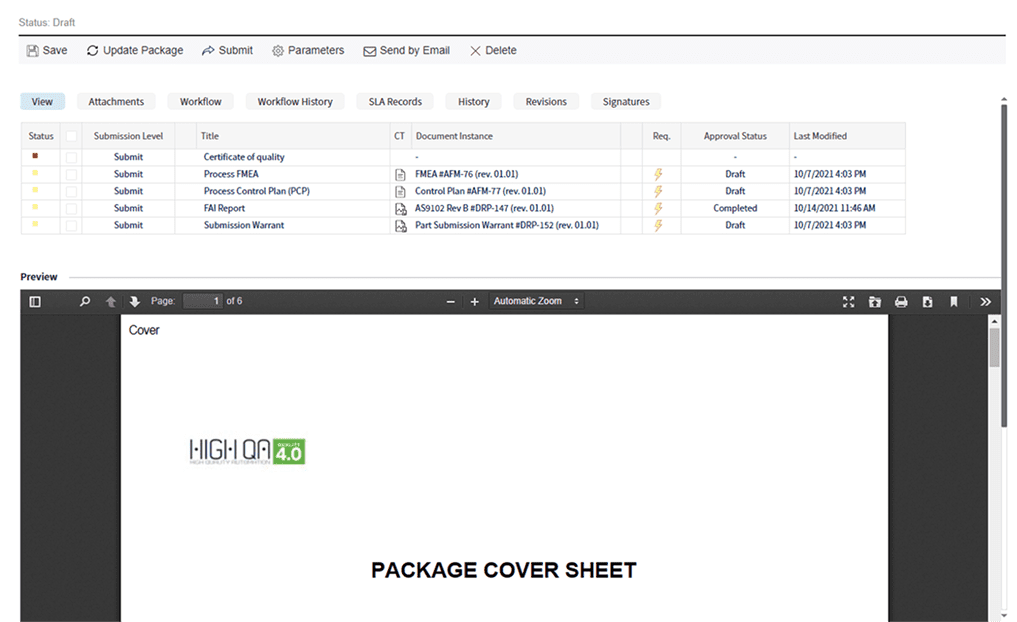

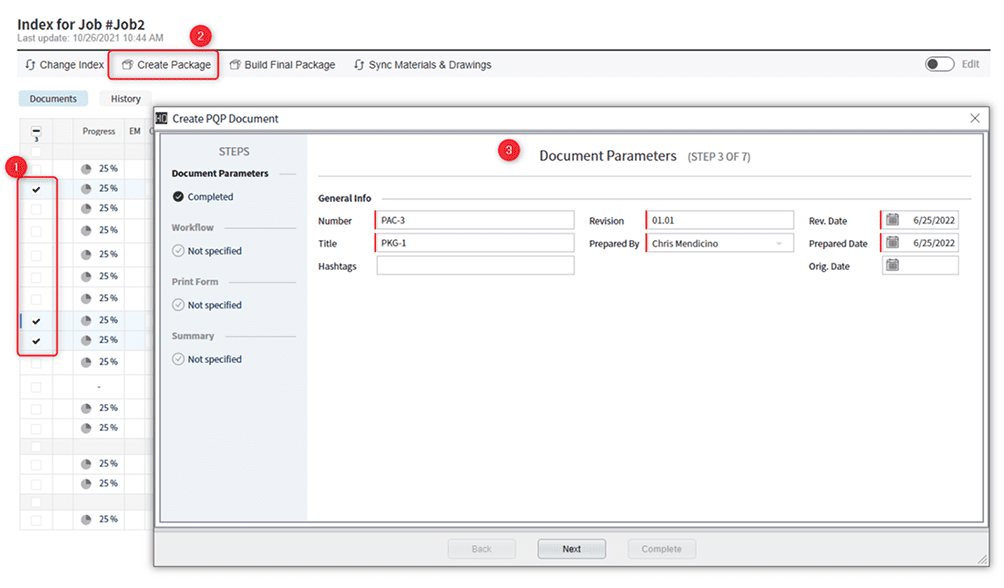

- Create comprehensive document packages, complete with cover sheets, for seamless customer submissions.

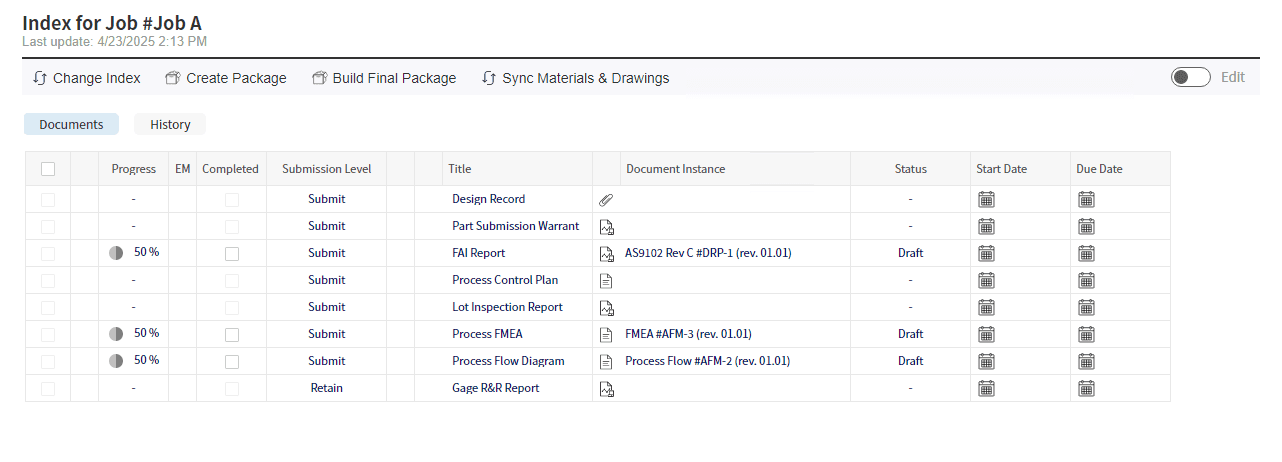

PPAP Document Creation Process

High QA simplifies the creation of critical PPAP documents by offering:

- Process Flow Diagrams (PFD): Automatically generate flow diagrams linked to manufacturing operations and synchronize changes with updates to processes.

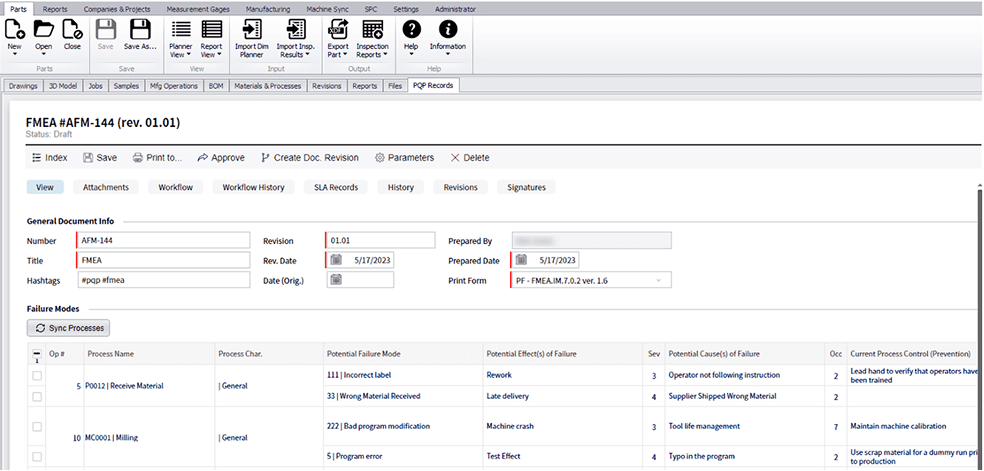

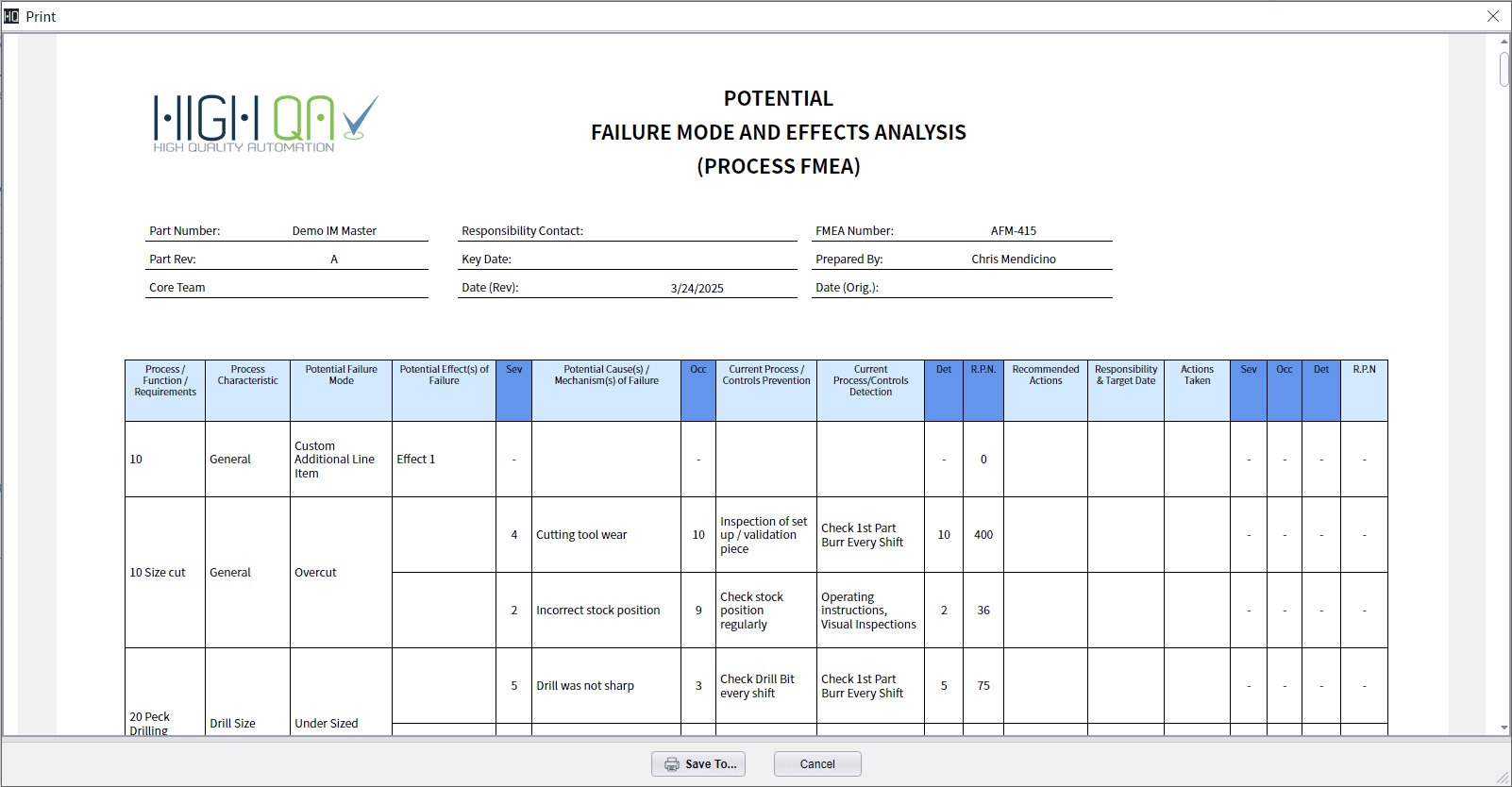

- PFMEA: Identify and evaluate potential failure modes, effects, and causes with tools for assigning Severity, Occurrence, and Detection values.

- Control Plans: Build detailed plans for monitoring manufacturing processes, including control methods and reaction plans.

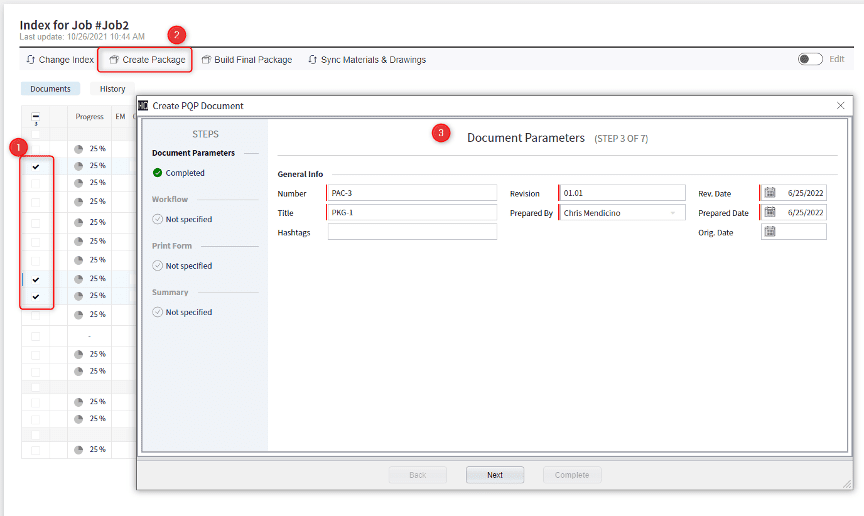

- Submission Packages: Group all PPAP documents into a single package for final approval, including dimensional results, material certs, and inspection data.

Streamline Your Approval Process

High QA’s PPAP tools are designed to save time and ensure accuracy:

- Template Libraries: Use preloaded templates for common PPAP documents or customize them to meet specific customer requirements.

- Dynamic Updates: Synchronize document changes with real-time updates from manufacturing operations.

- Audit-Ready Records: Maintain complete traceability with historical data and document revisions for every PPAP submission.

APQP:

Streamline Product Quality Planning with High QA

Overview

High QA’s Advanced Product Quality Planning (APQP) solution enables manufacturing teams to take control of the product lifecycle by planning and managing quality deliverables early and efficiently.

With everything from design records to control plans centralized in one digital platform, teams can accelerate new product introduction (NPI), ensure quality requirements are met, and achieve full customer satisfaction with less manual work and more collaboration.

Key Benefits

Centralized Documentation

- Store and manage all APQP documents in one place—from Process Flow Diagrams to PFMEAs and Control Plans.

Workflow Automation

- Track, assign, and automate tasks across teams to streamline the APQP lifecycle.

Compliance

Simplified

- Maintain compliance with IATF 16949 and AIAG guidelines with traceable documentation and version control.

Cross-Functional Collaboration

- Enable simultaneous access and updates by engineering, quality, and production teams.

Audit-Ready Reporting

- Automatically generate consistent, real-time reports for internal and customer audits.

Integrated with PPAP & Manufacturing Quality

- Seamlessly handoff deliverables to PPAP and ongoing production documentation.

Document Creation & Management

High QA enables users to digitally manage all phases and deliverables of APQP, including:

- Process Flow Diagrams

- PFMEAs (Process Failure Mode & Effects Analysis)

- Control Plans

- Design Records

- Dimensional Results

- Material Certifications

- Initial Process Studies

- Appearance Approvals

- Gage R&R and more

Collaborate Across Teams with Ease

Replace static spreadsheets and disjointed communication with a single system that keeps everyone on the same page. Users can:

- Assign ownership to tasks and documents

- Track progress across deliverables

- Communicate in-platform with notes and approvals

- Generate real-time status updates and audit trails

Seamless Submission and Handoff

Package Everything with One Click

Export all APQP deliverables into a single, well-organized submission packet for customers or internal reviews.

Handoff to PPAP or MSA

Ensure smooth downstream transition to High QA PPAP or other quality modules like Measurement Systems Analysis (MSA).

Discover More

Take control of your Production Part Approval Process (PPAP) with High QA’s integrated PPAP solution. Schedule a demo today to see how our tools can simplify document creation, improve compliance, and enhance collaboration across your organization.