IM / 360 CORE

Quality Management Solutions, Purpose-Built for Manufacturers

Plan collaboratively. Inspect seamlessly. Report automatically. Elevate quality—without slowing down production.

End-to-End Quality Management — from Design to Delivery

Everything you need to move faster, stay compliant, and deliver with confidence — all in one connected system.

Plan

Inspect

Report

Collaborate

Results That Matter to Modern Manufacturers

Faster inspections. Fewer errors. Complete control. Empower your quality and manufacturing teams to deliver parts 100% on time, on budget, and on quality.

See how much time and effort you could save

Features to Support Each Stage of Quality

From first part to final report, everything you need is right here. Explore the tools that help you plan smarter, collect faster, report confidently, and stay connected.

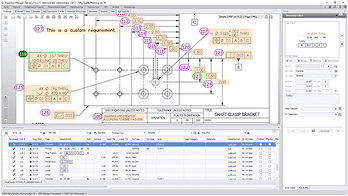

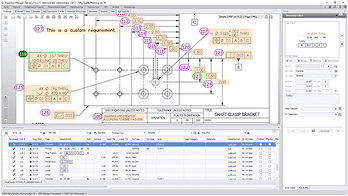

Automatic 2D/3D

Ballooning

Quickly balloon 2D drawings and 3D MBD models in one click to create complete inspection-ready documentation.

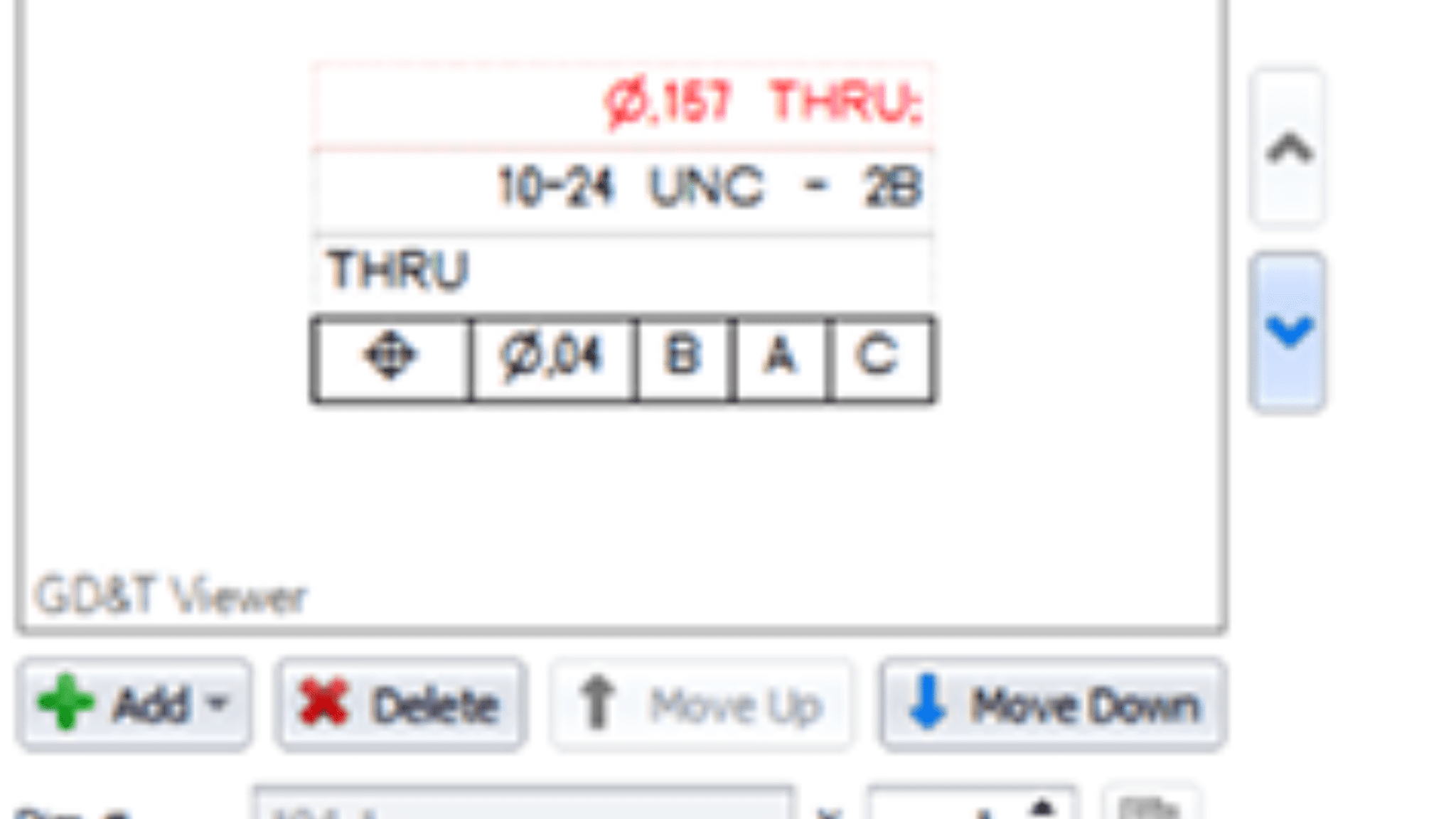

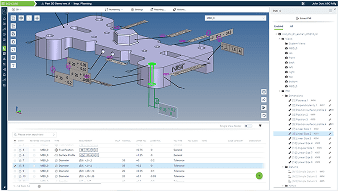

GD&T and PMI Extraction

Extract geometric tolerances and part manufacturing info directly from CAD models for precise inspection planning.

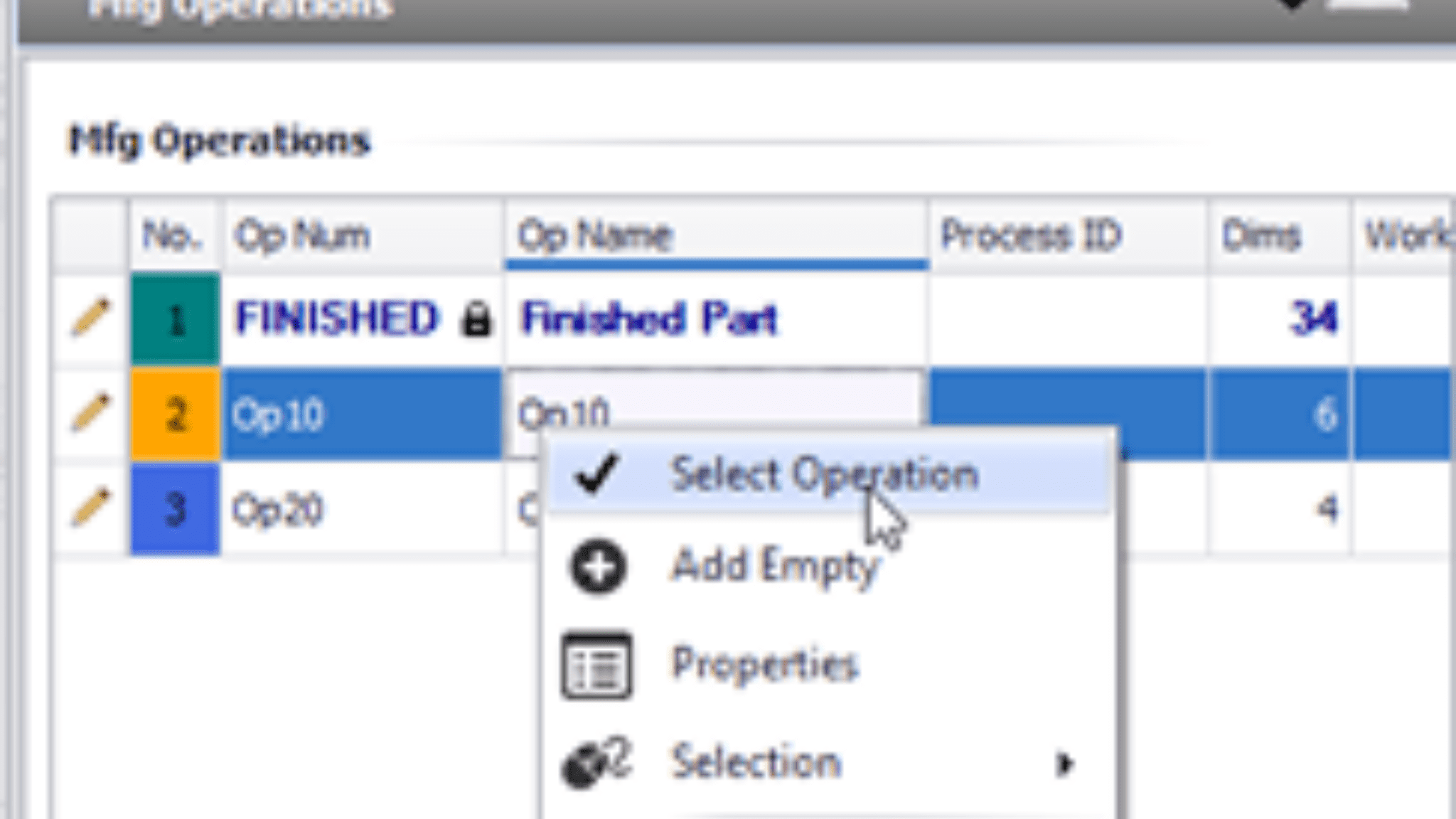

Operations &

Routings

Assign manufacturing operations to characteristics and route inspection steps by process stage or station.

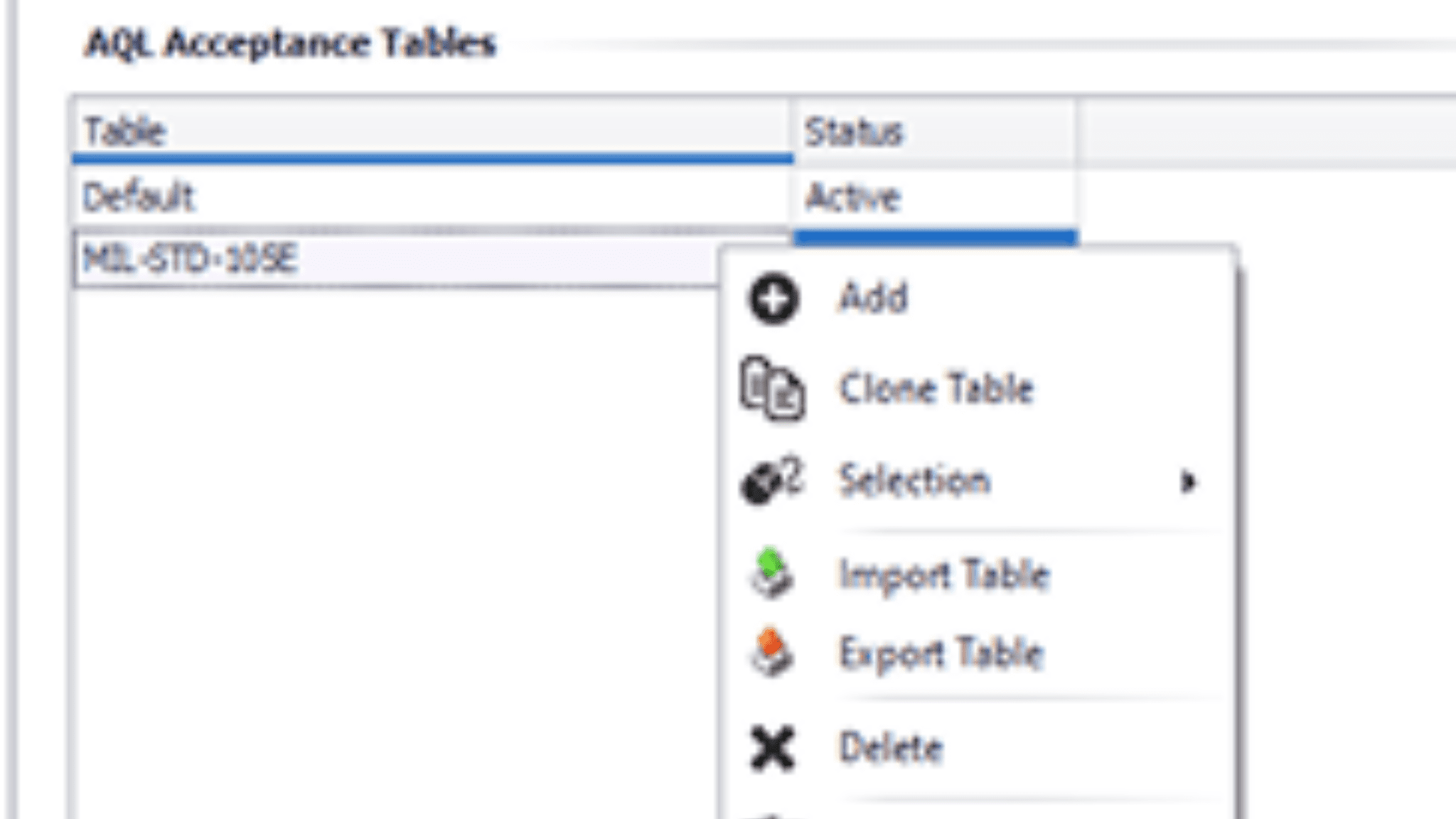

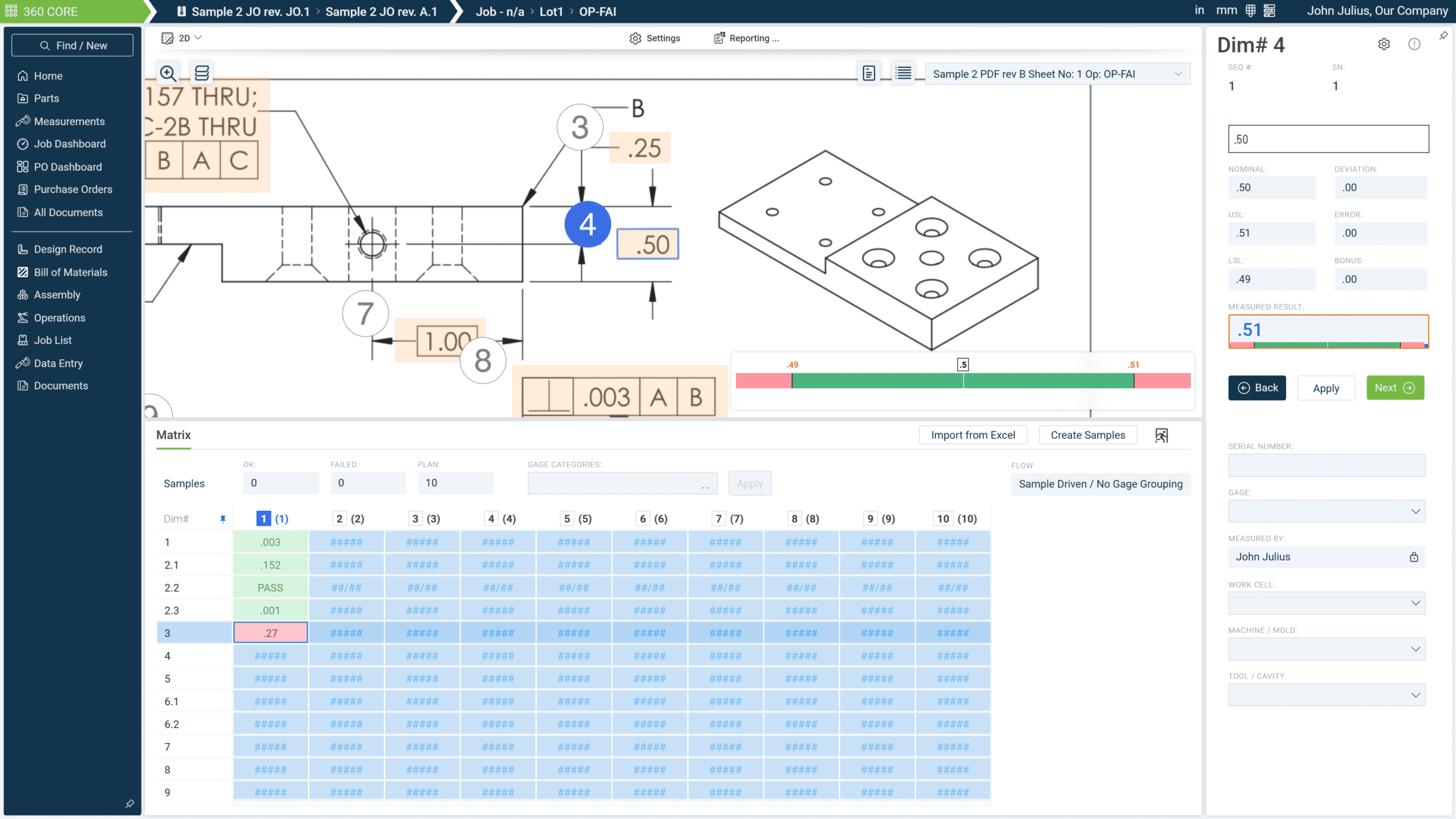

AQL Sample Planning

Define Acceptable Quality Limits (AQL) to generate intelligent, efficient sample sizes based on part, lot, or operation.

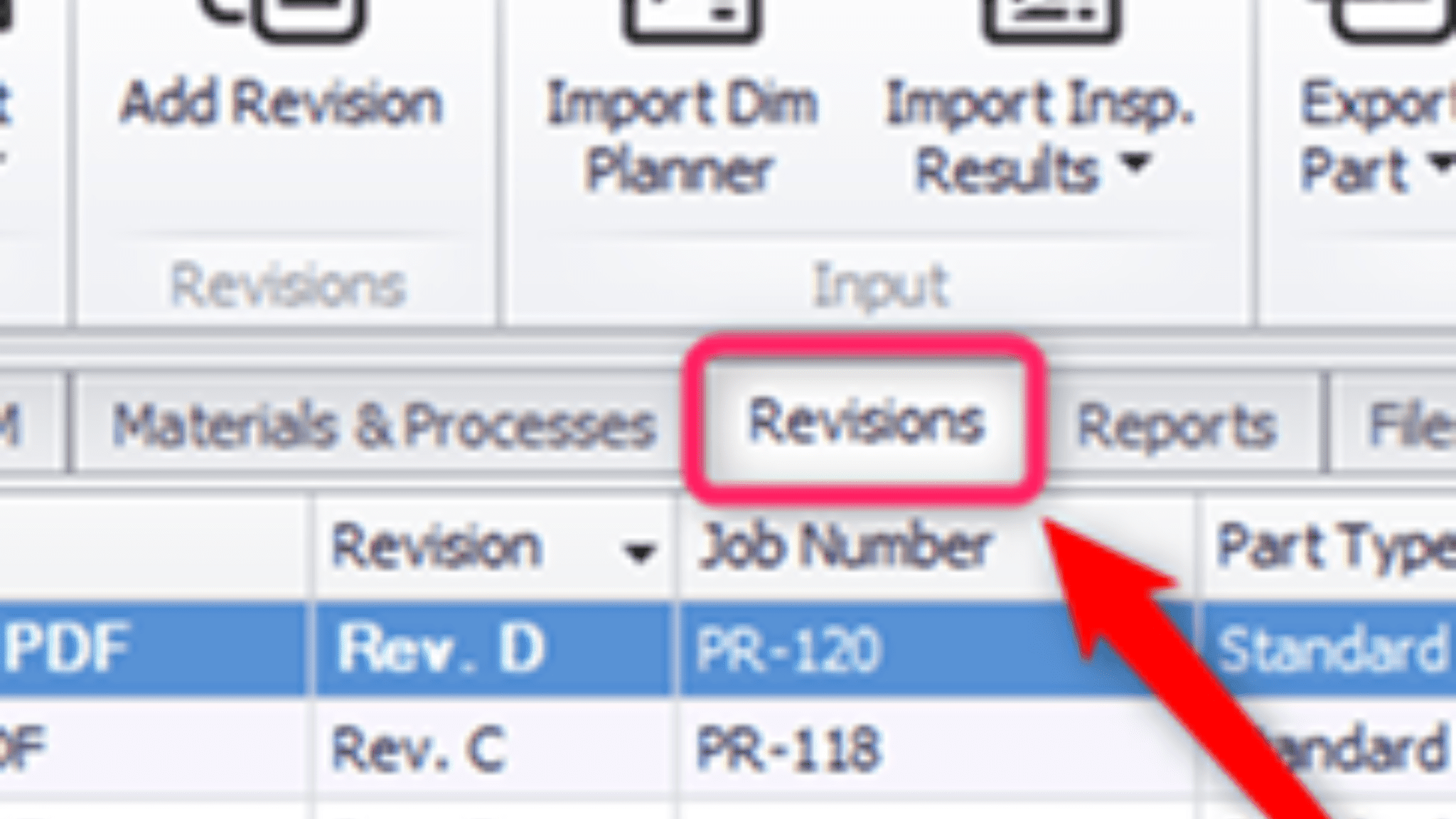

Part Revision Management

Track and control drawing and inspection plan revisions with complete version history and change traceability.

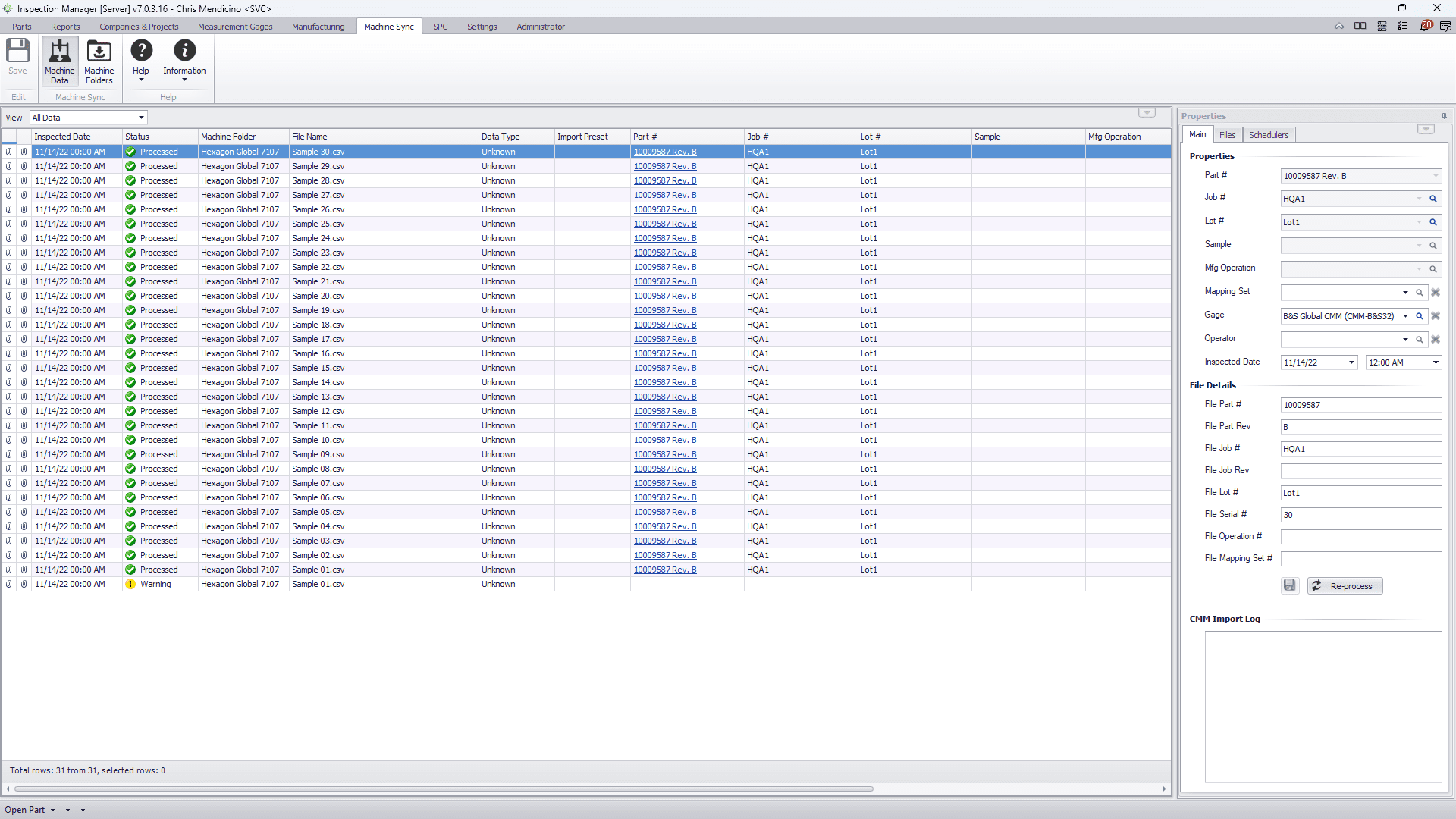

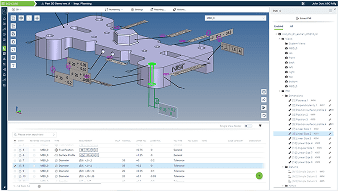

Automatic CMM Imports

Import inspection results directly from coordinate measure machines (CMMs), vision systems (VMMs), and other automated inspection equipment.

Shop Floor Data Collection

Capture inspection results with digital gages or via tablets on the shop floor — with built-in validation and user permissions.

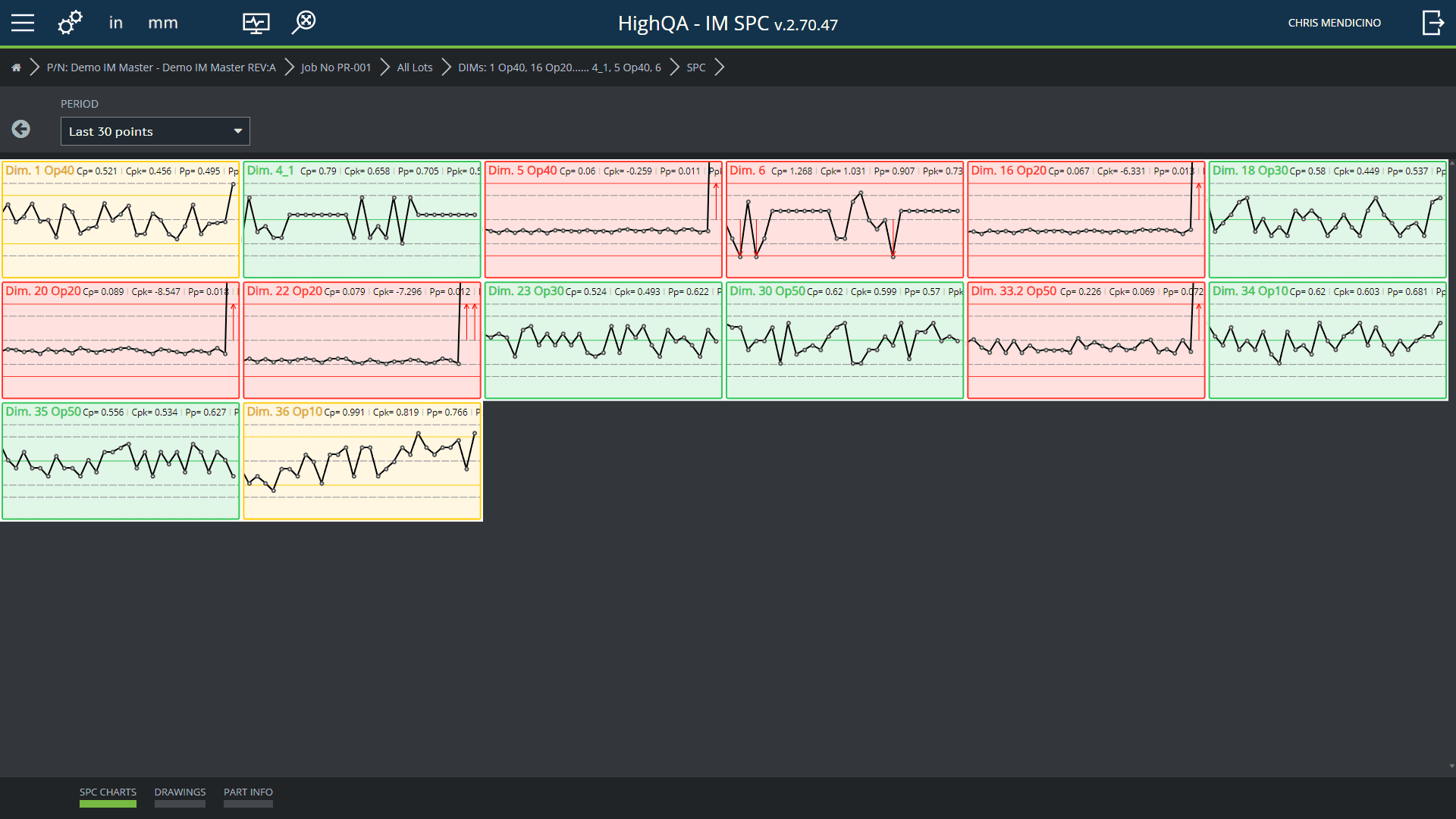

Real-Time SPC Monitoring

Track statistical process capability and controls with live Cp, Cpk, Pp, Ppk, and control chart updates from inspection data.

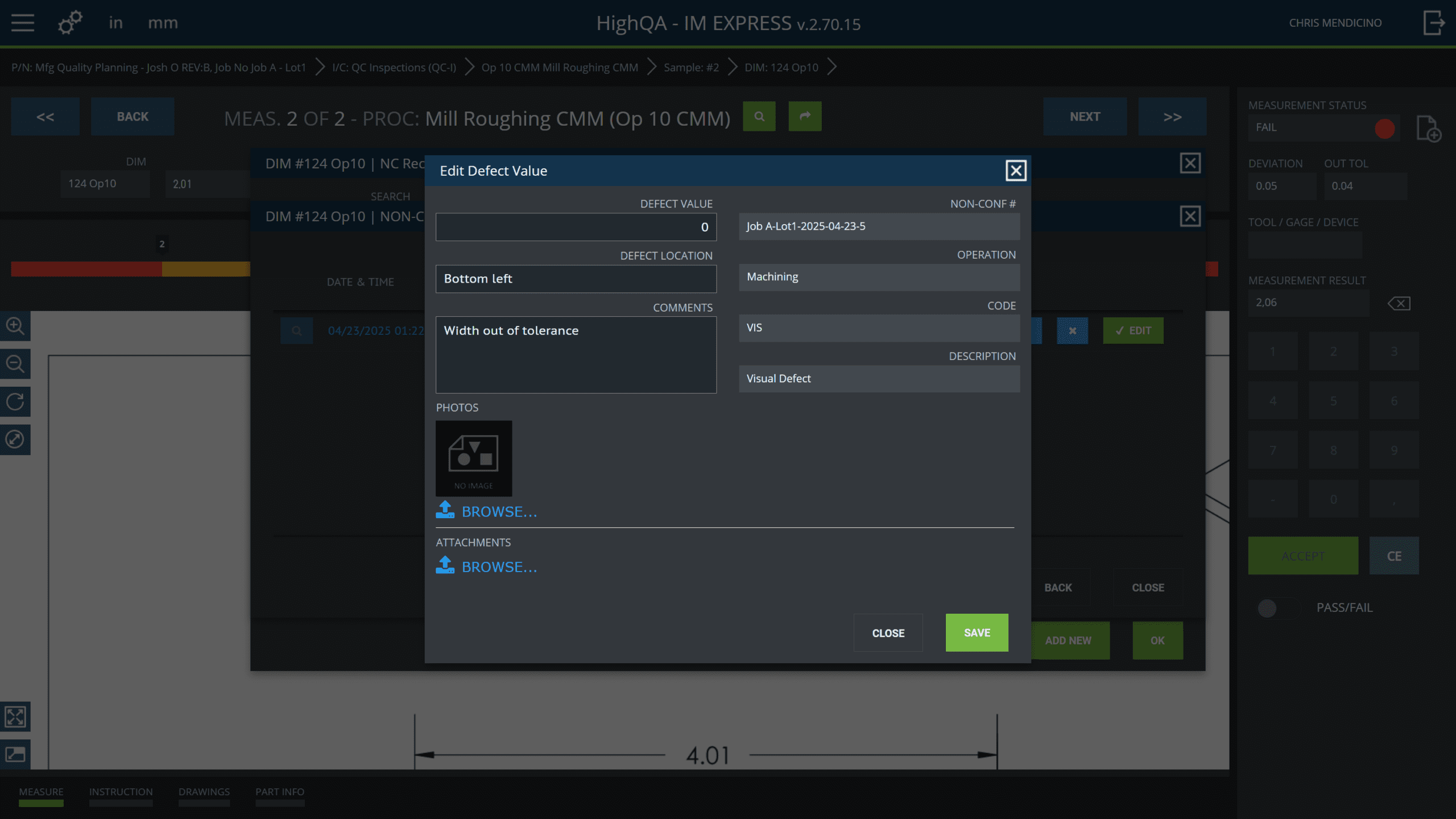

Non-Conformance

/Defects

Log, track, and analyze non-conformances with linked corrective actions and audit history.

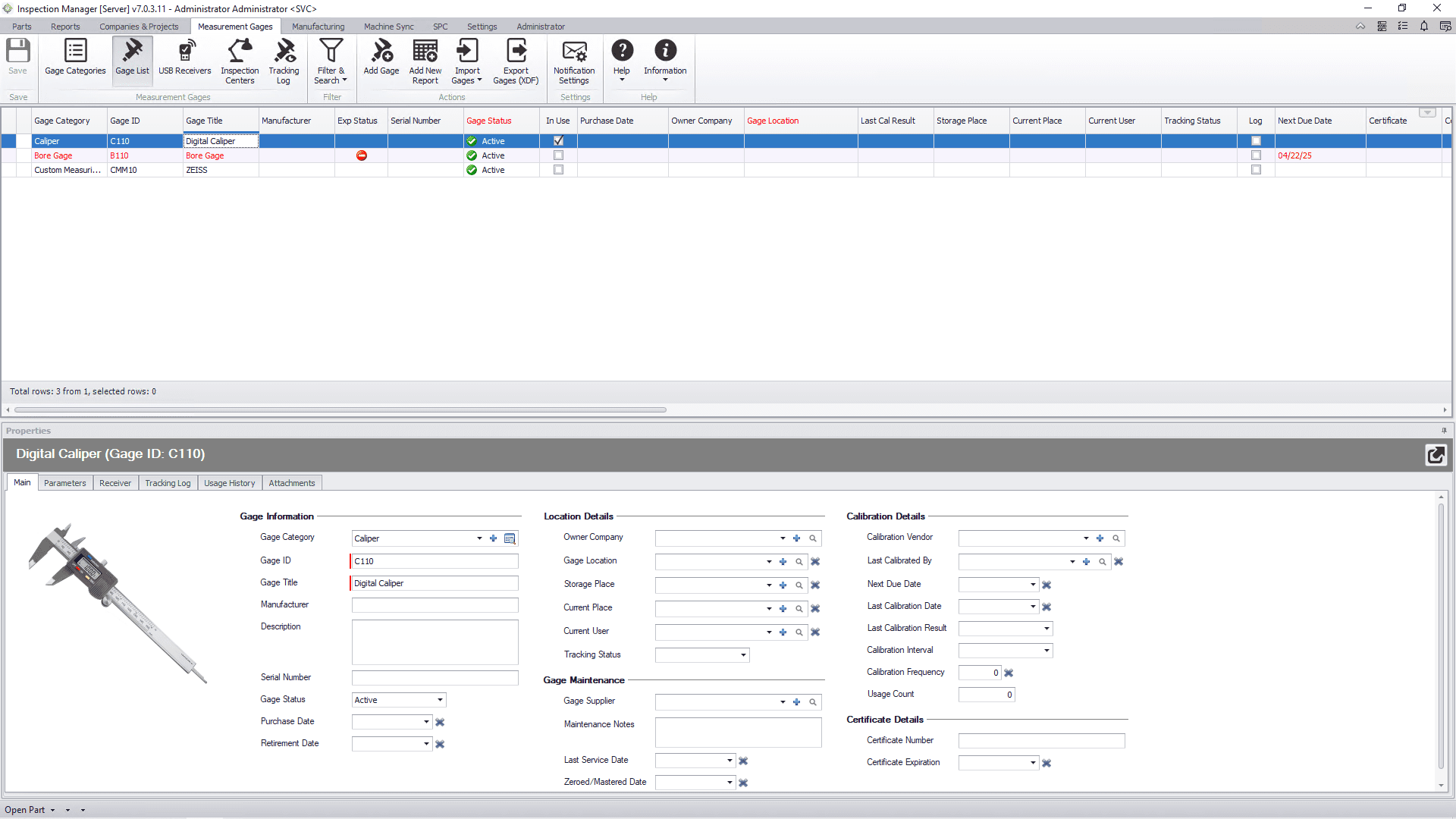

Gage & Tool Management

Maintain calibration records, assign tools to inspection steps, and monitor gage usage across jobs.

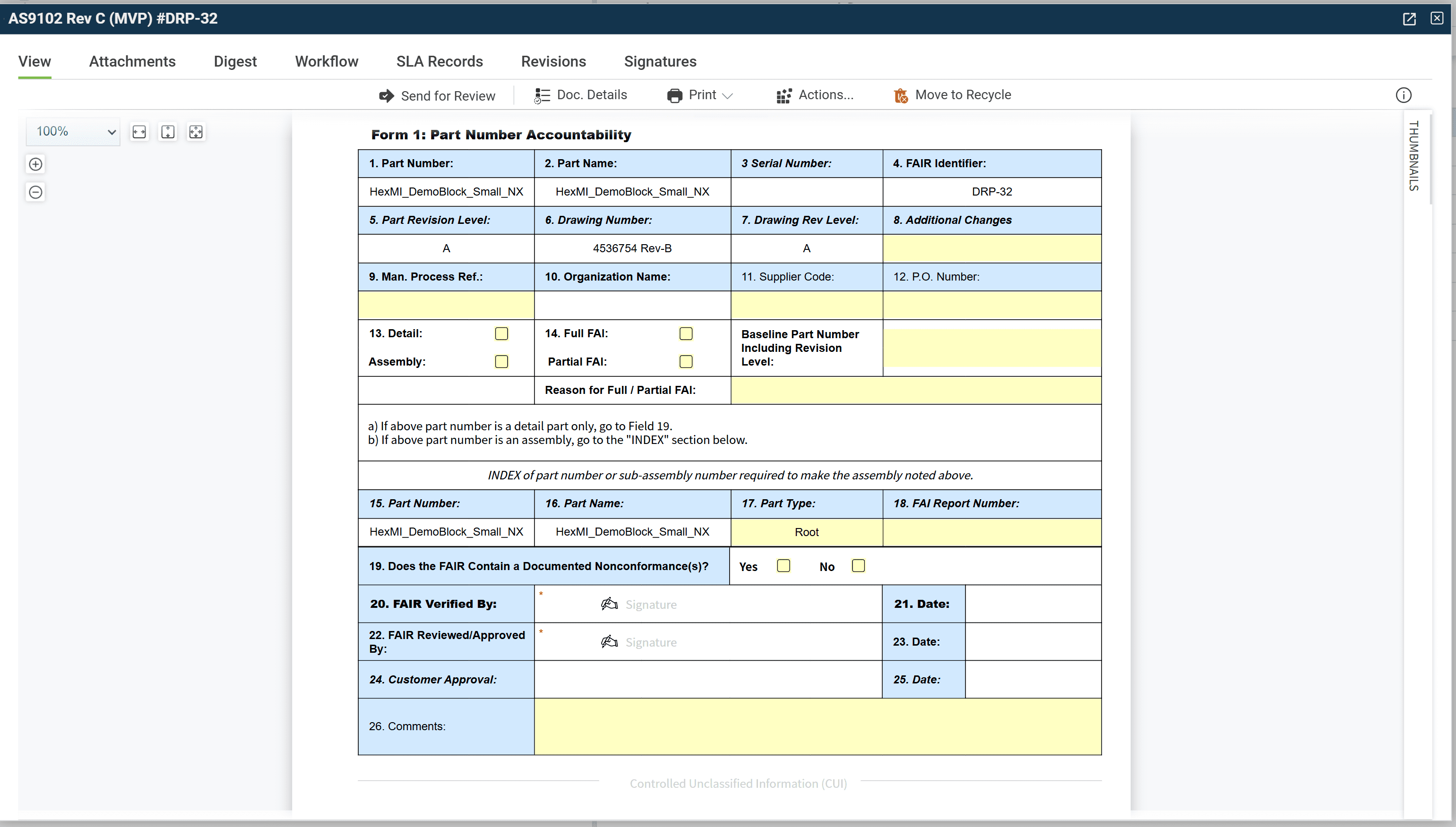

FAI and Lot Inspection Reports

Quickly generate AS9102-compliant First Article Inspection Reports and configurable in-process or lot inspection reports.

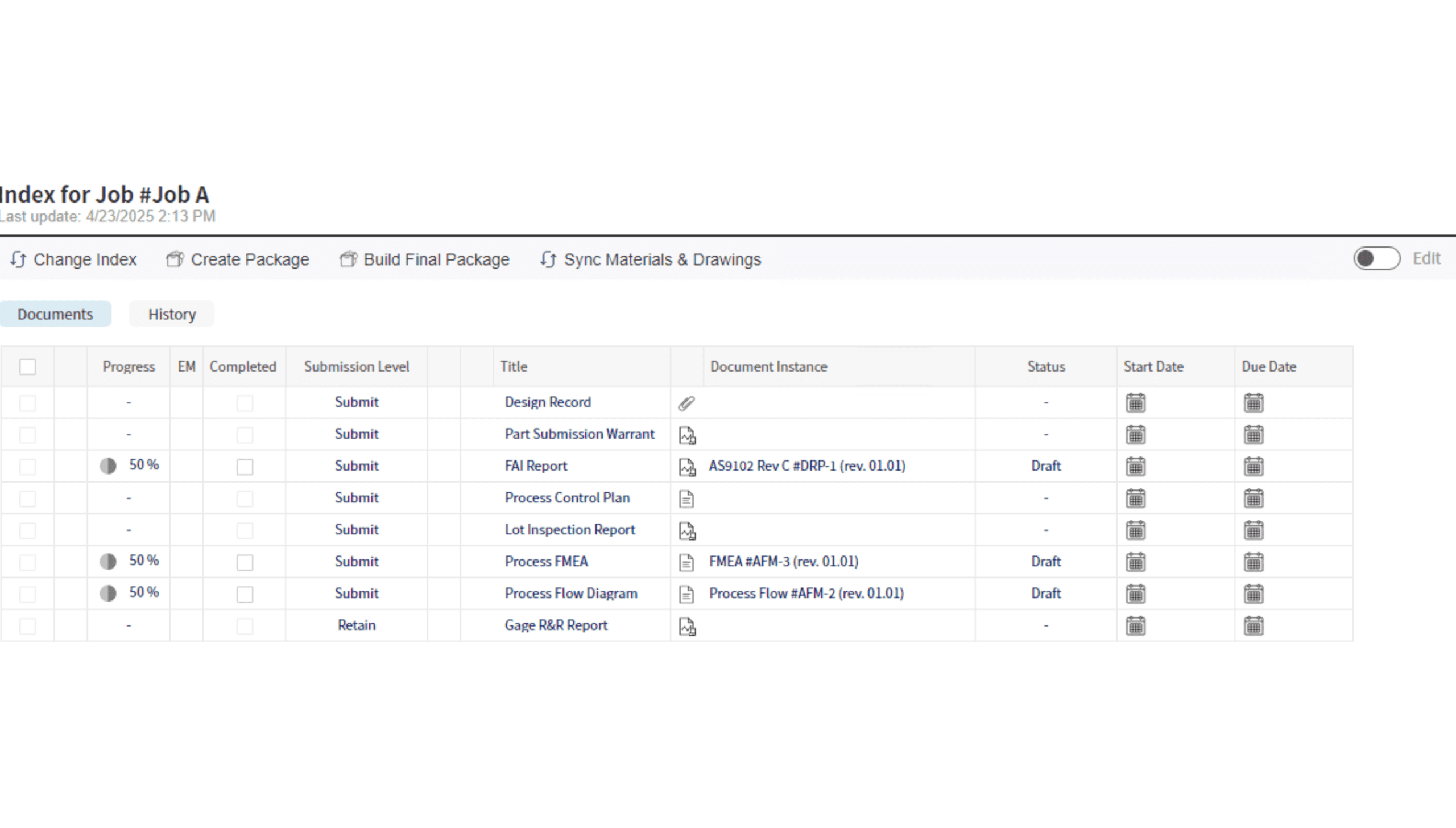

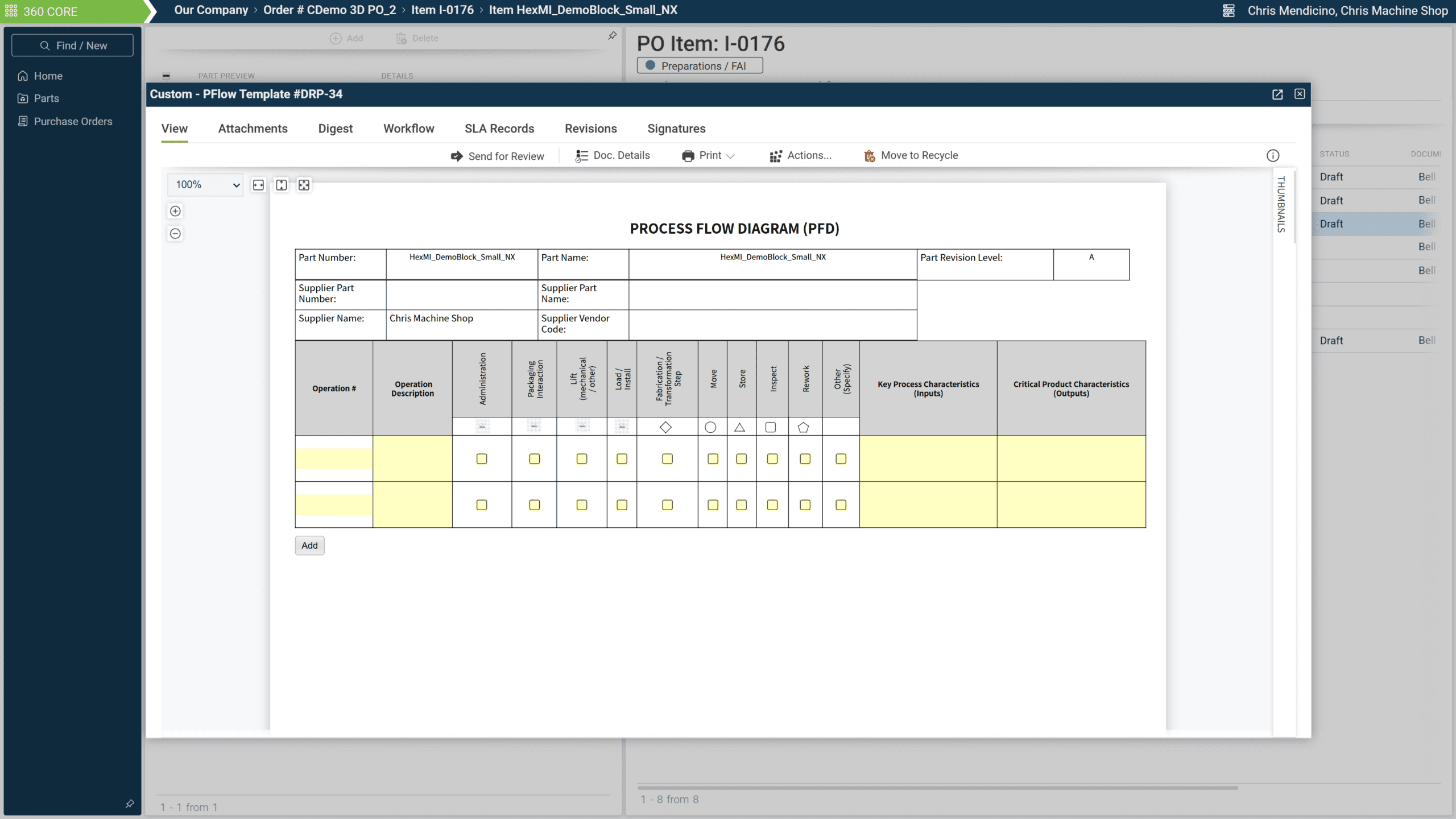

PPAP

Management

Build and manage full submission packages aligned with IATF 16949 and ISO 13485 requirements.

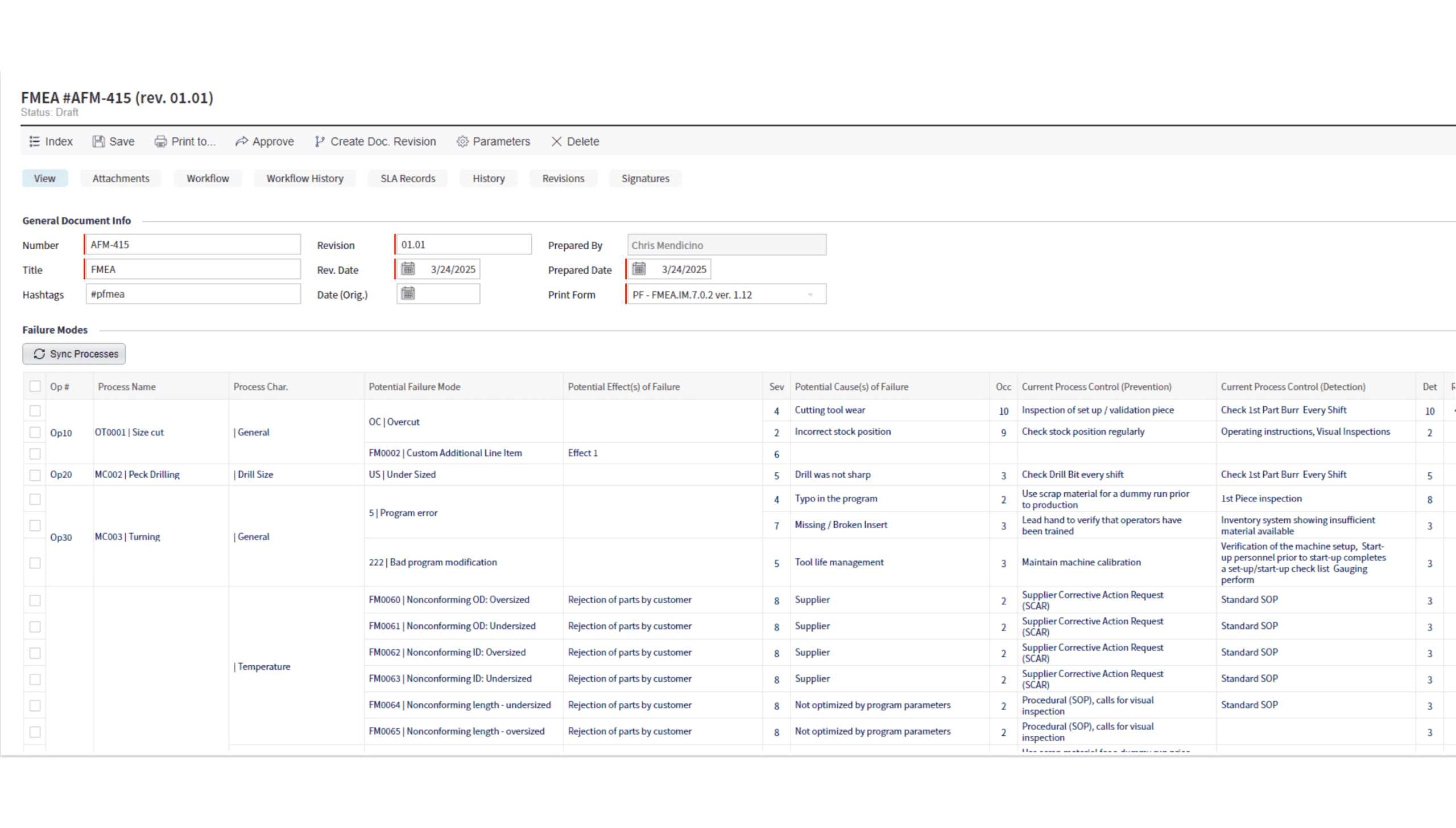

PFMEA

Automation

Digitize PFMEAs with auto-linked controls, risks, and characteristics across operations and jobs.

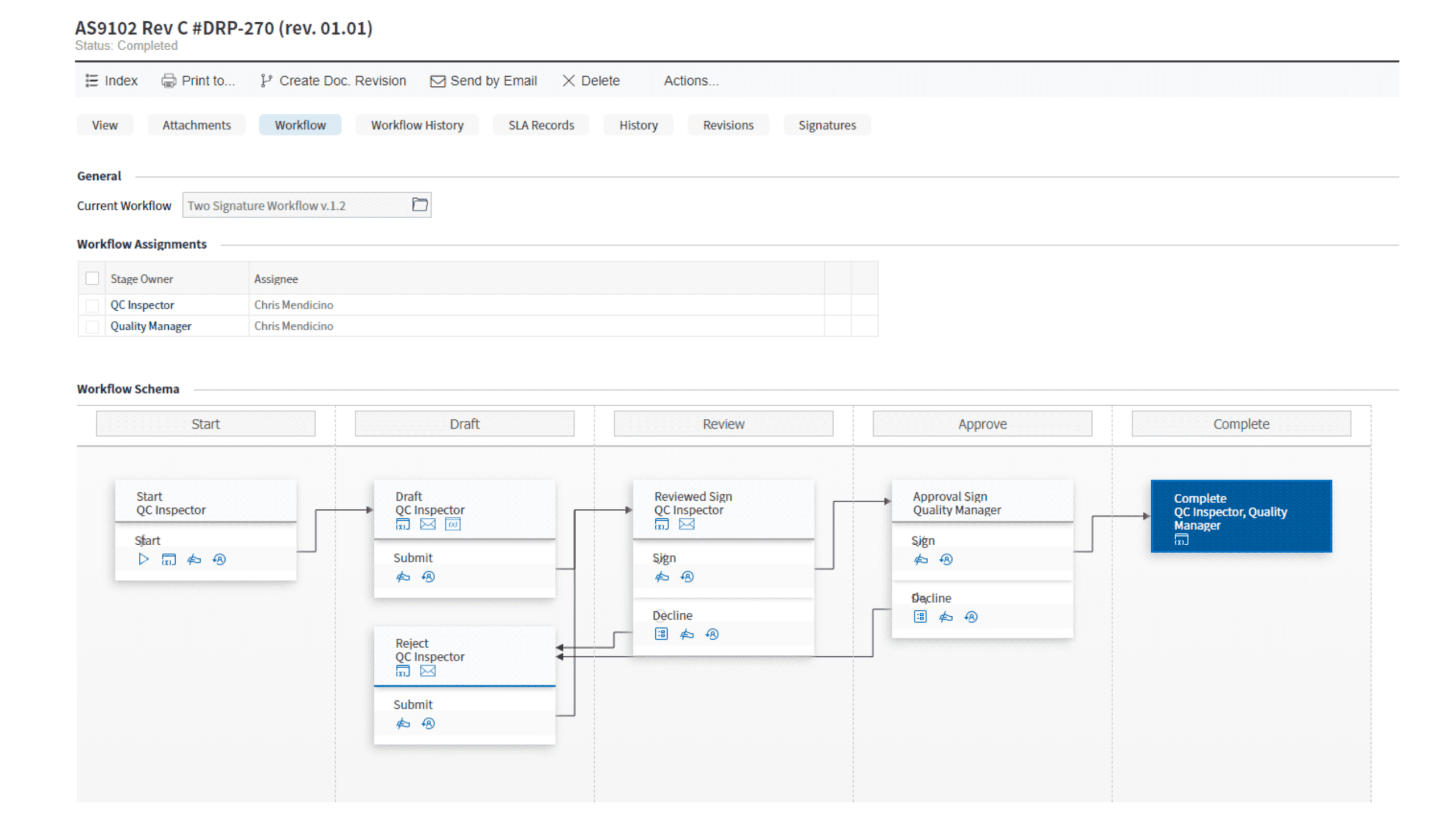

Digital Workflows & Signatures

Assign reviews, approvals, and sign-offs with digital traceability and multi-role workflows.

Custom Report Templates

Generate branded reports with drag-and-drop fields, custom logic, and reusable templates.

Features to Support Each Stage of Quality

From first part to final report, everything you need is right here. Explore the tools that help you plan smarter, collect faster, report confidently, and stay connected.

Two Options. Same Powerful Results.

High QA offers two interface options to match the way your teams work: IM (our Windows-based solution) and 360 CORE (our Browser-based solution).

Need help choosing the right experience?

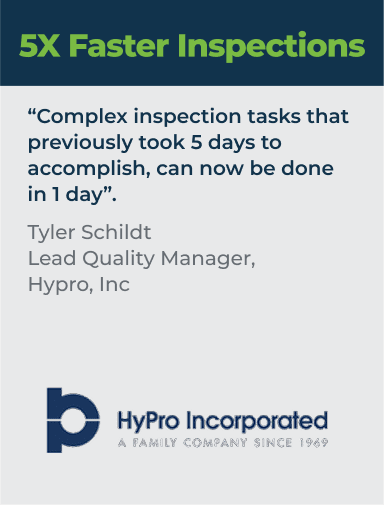

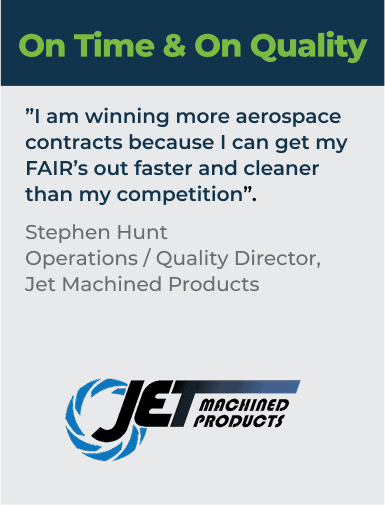

Trusted by Manufacturers

Who Can’t Afford to Slow Down

Join the 1600+ manufacturers using IM and 360 CORE to deliver faster inspections, cleaner submissions, and fewer quality headaches. Here’s what they’ve achieved.

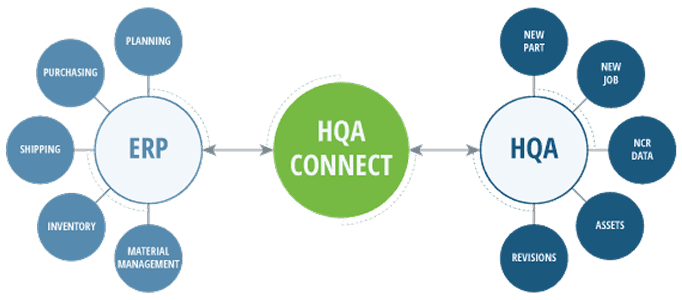

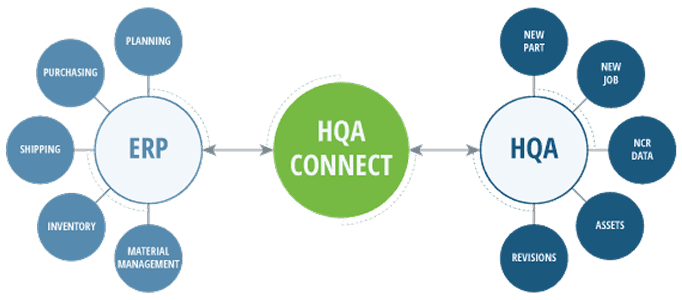

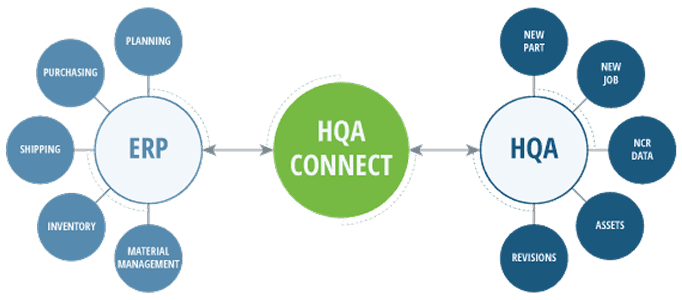

Works With the Systems you Already Use

Connect seamlessly to your existing tools. Whether you’re working with ERP, MES, CMMs, or CAD data, we integrate into your ecosystem and keep your quality process moving.

ERP & MES Integration

CAD & PLM Compatibility

CMM & Metrology Tools

Secure, Compliant, and Built for Manufacturing

We know that in manufacturing, quality isn’t enough — your systems need to be secure, traceable, and audit-ready. That’s why our products are built to meet the security and compliance standards you already live by.

CMMC 2.0 & ITAR READY

Designed for manufacturers handling export-controlled data and cybersecurity-sensitive work. Supports secure deployments, role-based access, and air-gapped infrastructure.

ISO & AS Compliant

Supports the process and documentation requirements of ISO 9001, AS9100, IATF 16949,

and more.

Access Control & Audit Trails

Role-based permissions, login tracking, time stamps, digital signatures, and revision history — built in and audit-ready.

Flexible Deployment Options

Choose from on-premises, private cloud, or cloud-first models to meet your organization’s

IT policies.

Effortless ISO/AS Compliance

”With all the complexities that come with generating an aerospace first article inspection (FAI), High QA really holds your hand through the whole process and makes sure it’s done per the ISO/AS standard. It’s just a no-brainer for us.

– Tim Rousseau, Founder and Owner, Above All CNC”.

Connected Quality, Inside and Out

Managing supplier quality shouldn’t mean chasing emails, PDFs, and outdated revisions. Whether you work with five suppliers or five thousand, High QA brings consistency, visibility, and speed to your submission and approval process — all within 360 CORE.

Let’s Build a Better Quality Process — Together

Across every stage of manufacturing quality, we’ll partner with you to move faster, stay compliant, and deliver parts with confidence.