Why Should You Connect Your ERP with Your Manufacturing Quality System?

In the fast-paced world of modern manufacturing with expensive materials, many jobs, and very slim margins for errors, maintaining a competitive edge requires more than just skilled management – it demands a seamless integration of key operational elements.

Operational Silos and Quality Compromises

In many manufacturing organizations, the lack of integration between QMS and ERP systems gives rise to operational silos. This division can lead to critical quality lapses, product “lates,” material waste and reduction of overall productivity. To operate an effective business, data and digital content needs to be accurate, consistent, relevant, accessible, and not duplicated. It needs to be entered seamlessly and not manually entered.

Imagine a scenario where the manufacturing quality data is housed in one system while administrative and operational data resides in another with a human in the middle needing to reconcile the data manually. It is a recipe for miscommunication, data errors, and compliance issues. This disjointed scenario not only jeopardizes product quality, cost, and delivery times, but also places unnecessary burdens on compliance and audit efforts.

The Compromise Cost

The effects of such disjointed systems are far-reaching. Audits become a tedious affair, riddled with inefficiencies and potential errors. The fallout? Hefty fines, tarnished reputation, and an erosion of customer trust. Additionally, the inability to quickly identify and address manufacturing quality issues can result in increased product recalls with subsequent financial setbacks. At a time when the market demands agility, these setbacks are not just inconveniences; they’re potential deal-breakers.

Unity Through Integration

The remedy to these challenges can be found in the seamless integration of QMS with ERP systems. By fostering collaboration between these two fundamental pillars of business and manufacturing operations, organizations can establish a unified digital thread that diminishes data silos. Quality data then becomes a central part of the entire operational workflow, ensuring that decision-makers have real-time insights into both manufacturing quality and operational metrics.

Let’s think about a scenario where every department, from manufacturing to distribution, is synchronized in real-time, sharing a cohesive data thread. The result? Swift identification and resolution of quality issues streamlined compliance processes, and a proactive approach to risk mitigation. The integration of critical systems doesn’t just bridge the gap – it propels the organization into operational excellence.

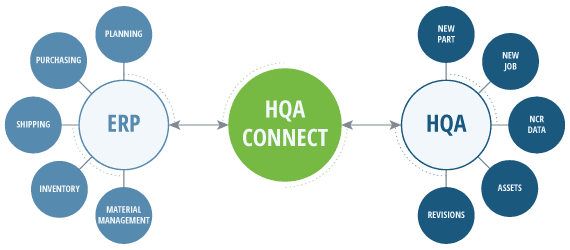

Example: Connecting QMS and ERP with HQA Connectors

As we have seen thus far, the integration of ERP and QMS is not just a technological feat; it’s a strategic imperative. The cost of compromise is high, both financially and reputationally. The cost of integration can also be high with the wrong partners. Integrations with custom code or ERP supplied connectors to QMS systems can reach over 6 figures ($100k+) and take months to implement.

Fortunately, using a modern QMS system, like HQA 360, and a modern ERP system with options for open architecture (or APIs) is much easier. For example, creating a new job in HQA 360 software is a swift process, taking only a few minutes. Copying and pasting data from QMS to ERP is relatively common. However, when running hundreds or thousands of jobs each month, that time adds up quickly. As a result, parts are late and working capital goes up.

The HQA ERP Connector removes uncertainties tied to manual job creation. The fear of inadvertently skipping a job, succumbing to typographical errors, or overlooking a critical revision on a new order is now a thing of the past. It seamlessly bridges the gap, performing these intricate tasks automatically between the two systems in the background. The result? More automation, freeing up more time to redirect focus towards tasks of greater significance, and increased productivity!

The Desired Outcome

The manual burden is lifted, allowing quality teams to devote energy to the strategic imperatives that drive businesses forward such as better Reporting and Analytics, and improved utilization of manufacturing machinery.

The HQA ERP Connector is a supported software product, with a lifecycle, enhancements and improvements. It is highly secure and should support compliance needs.