AS13100 is the latest aerospace standard to be released. This standard creates a common set of supplemental requirements to improve understanding, efficiency, and performance.

The primary intent of this new standard is to improve overall product quality, by focusing on the key systems and processes currently deterring consistent aerospace engine product quality.

AS13100 will be a required supplement to AS9100 and AS9145 that focuses on customer specific requirements for aircraft engine OEMs.

Along with the industries key standards of AS9100 and AS9145, the recent released AS13100 is designed to prevent defects and waste. Integrating this new standard is essential in developing, maintaining and improving a more effective and efficient QMS.

Do You Have To Follow The AS13100 Standard?

Given that AS13100 is a voluntary standard, manufacturers are not obligated to abide by it. However, many businesses in the aerospace and defense sectors decide to put the standard into practice in order to show their dedication to quality and to live up to consumer and regulatory expectations.

What are the benefits of following the AS13100 standard?

Implementing the AS13100 standard can provide several benefits to an organization, such as:

- Improved Quality: By implementing the standard, you can establish and maintain an effective quality management system that helps ensure products meet customer and regulatory requirements.

- Improved Customer Satisfaction: You are better able to understand customer requirements and meet or exceed those requirements, which leads to increased customer satisfaction.

- Improved Efficiency: Identifying and eliminating inefficiencies in quality processes often leads to cost savings and improved productivity.

- Improved Competitive Advantage: Demonstrating your commitment to quality to customers and regulators can lead to a competitive advantage in the marketplace.

- Improved Compliance: The standard helps you comply with applicable laws, regulations, and industry standards, which can reduce the risk of costly non-compliance issues and part recalls.

- Improved Risk Management: By identifying, assessing and managing risks, you can reduce the likelihood of incidents and accidents, and mitigate the impact of those that may occur.

What Is In AS13100?

Many of the needed documents and reports in the AS13100 standard can be found in the PPAP requirements.

Design Records

Engineering Changes

Engineering Approval

DFMEA

Process Flow Diagram

PFMEA

Control Plan

MSA and Gage R&R

Dimensional Results (FAI)

Material / Performance Records

Process Capability Study

Qualified Laboratory Reports

Appearance Approval Report

Sample Production Parts

Master Sample

Checking Aids

Customer Requirement

Part Submission Warrant

The most common PPAP submission package is Level 3. A level 3 PPAP contains 16 of the 18 elements with only “master sample” and “checking aids” being omitted. The AS13100 standard incorporates these 16 PPAP requirements.

Why AS13100 can be a challenge?

All of the required PPAP reports have to be generated. That is a great deal of paperwork just for one single part. And some of the documents are more time consuming and challenging than others.

- Process Flow Diagram

- Control Plan

- PFMEA

- MSA (Gage R&R)

- Process Capability Study

- Part Submission Warrant

Often times, prints are ballooned in one software, measured in another, with data compiled in another software or put on a PDF that has to be manually transferred to an FAI. SPC is calculated in another software, gages are tracked manually or in a standalone software while Gage R&R is calculated and compiled in yet another software.

There are so many different forms, spreadsheets, documents and lists that need to be maintained, tracked and coordinated.

High QA Helps Simplify AS13100 Documentation

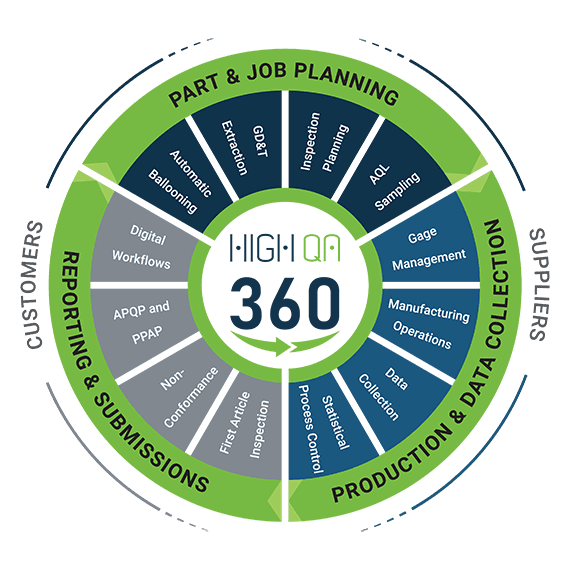

High QA software helps you automate your manufacturing quality process and streamline all the reports and documents required by regulatory standards and customer requirements.

High QA software provides the tools to digitize the quality process and increase collaboration throughout your organization.

From the time you acquire the information from your customer, the collaborative digital lifecycle begins. It usually starts by receiving a 2D drawing or 3D model from your customer.

Then you can begin the planning phase with one-click to balloon the drawing, extract the information from it (including the GD&T), create inspection plans, assign measurement methods and sampling rates.

On the production side, you can manage all the gages in your facility, collect all the inspection data, and provide SPC data, including notification for out of tolerance conditions.

Once the plan is made and the data is collected, this information is used to generate the submission package. No more spreadsheets with multiple tabs and pages, everything is in a database. Everything that is done is live and real-time in the database.

Now you can simplify and automate your part submissions and become compliant with the AS13100 standard or any other industry standard. That makes you more efficient, more profitable and successful.

If your company wants to achieve higher profitability and growth, let us show you how integrated manufacturing quality software works by requesting a demo now or visiting us at major industry events.