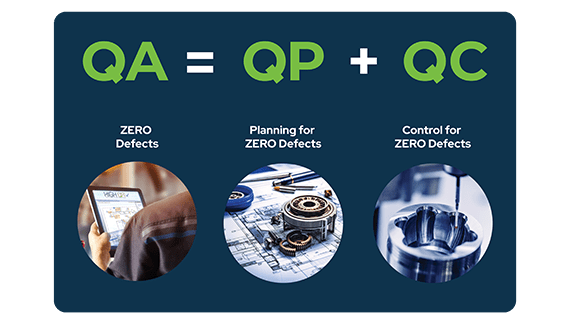

High QA Blog:

Simplify Inspection

Planning

High QA Blog: Spotlight on Aerospace & Defense Manufacturing Quality

Request a demo of High QA software today!We all read the same news: In the aerospace sector, where a quality-related defect in a small part such as...

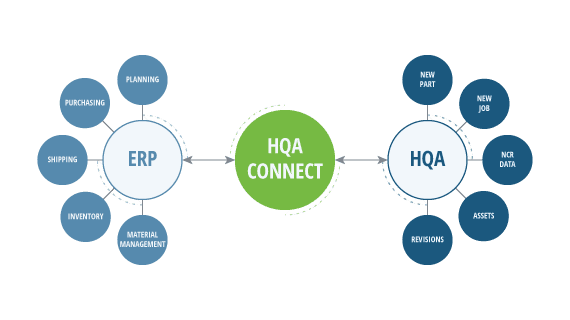

High QA Blog: Why Should You Connect Your ERP with Your Manufacturing Quality System?

Request a demo of High QA software today!In the fast-paced world of modern manufacturing with expensive materials, many jobs, and very slim margins...

High QA Blog: Simplifying Ford PFMEA Requirements

Request a demo of High QA software today!As you are probably aware by now, Ford Motor Company released their Customer-Specific Requirements for the...