NCR & Defects

Management:

Drive ContinuousImprovement

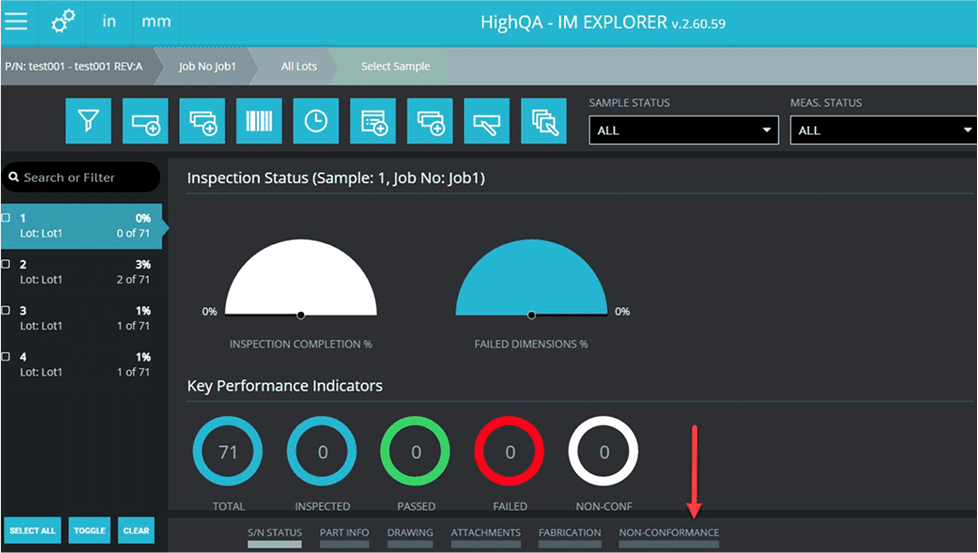

High QA’s NCR & Defects Management tools empower manufacturers to proactively identify, report, and resolve quality deviations. Integrated with IM/ 360 CORE, these features provide seamless workflows to address non-conformance issues efficiently and improve process stability.

Overview

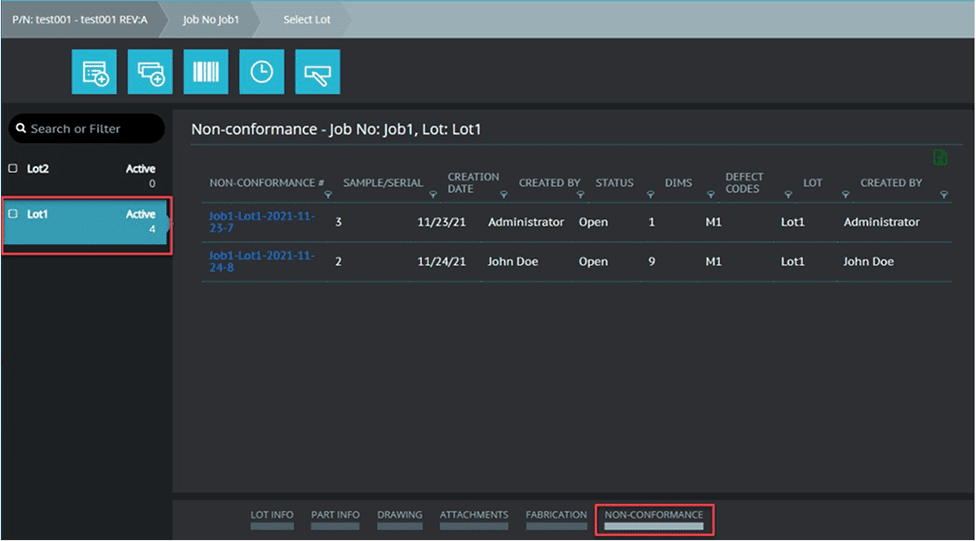

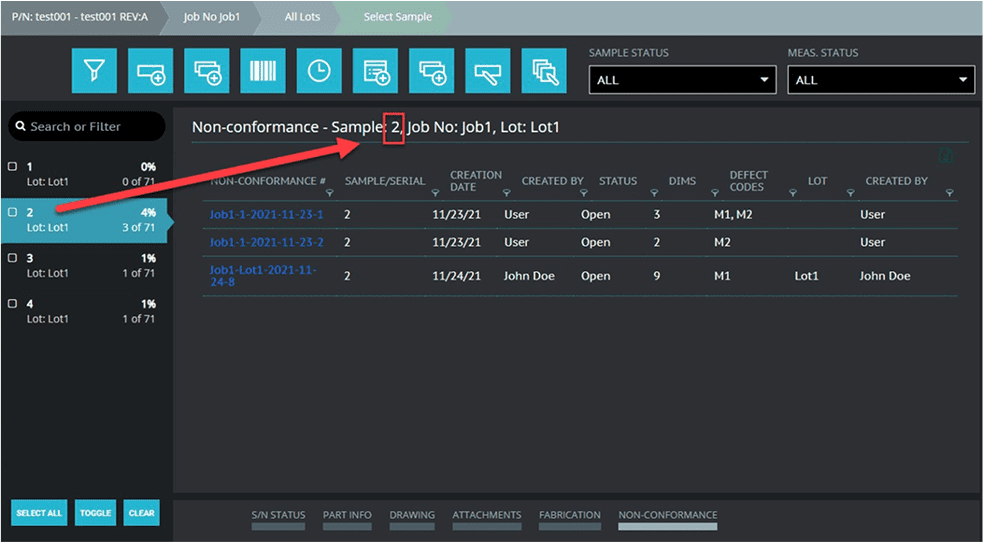

Non-Conformance Reports (NCRs) and defect tracking are essential for maintaining production quality and ensuring compliance with industry standards such as AS9100 and ISO 9001. High QA simplifies these processes by centralizing defect data, automating notifications, and enabling teams to implement corrective actions quickly. Tools like IM Explorer and IM Express allow inspectors and quality managers to access NCR workflows in real time, which helps to ensure accurate data capture and streamlined resolution of defect-related issues.

Key Benefits

Centralized Defect Management

- Access all defect and NCR data in one platform for improved traceability and visibility.

Real-Time Data Collection

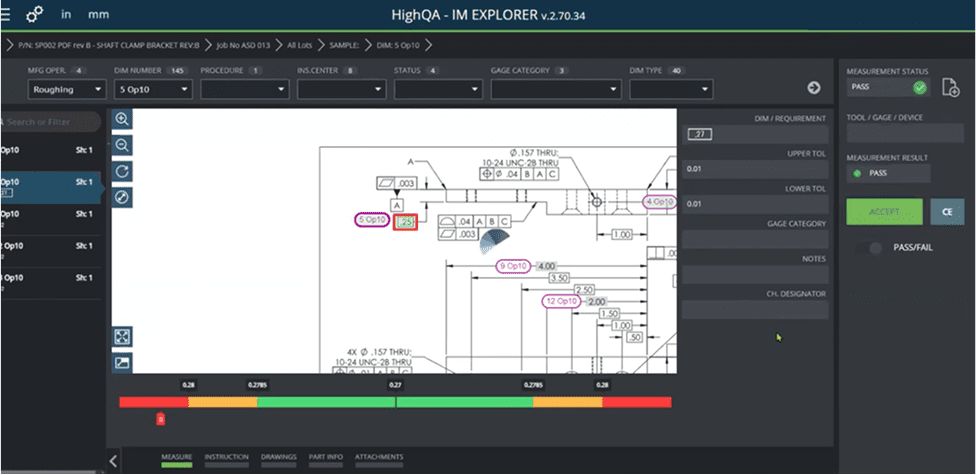

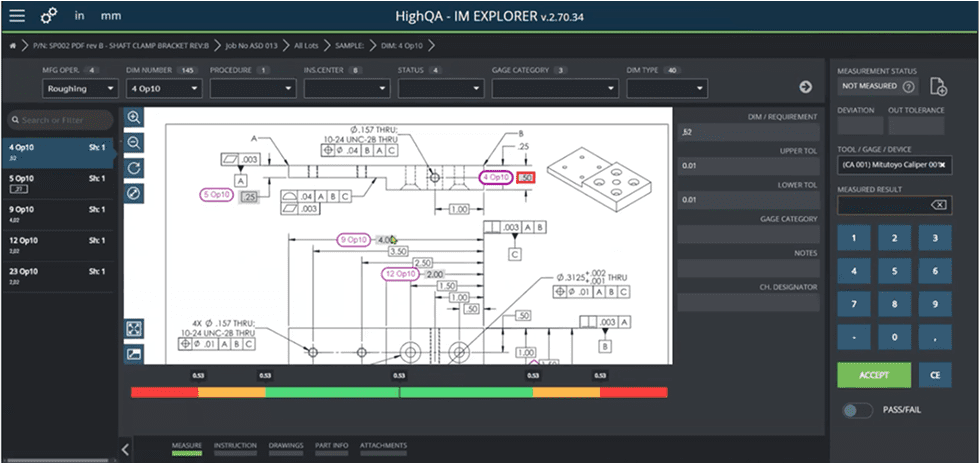

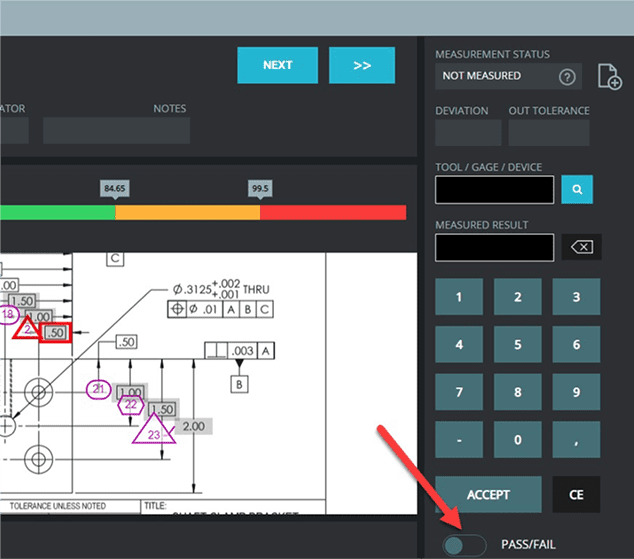

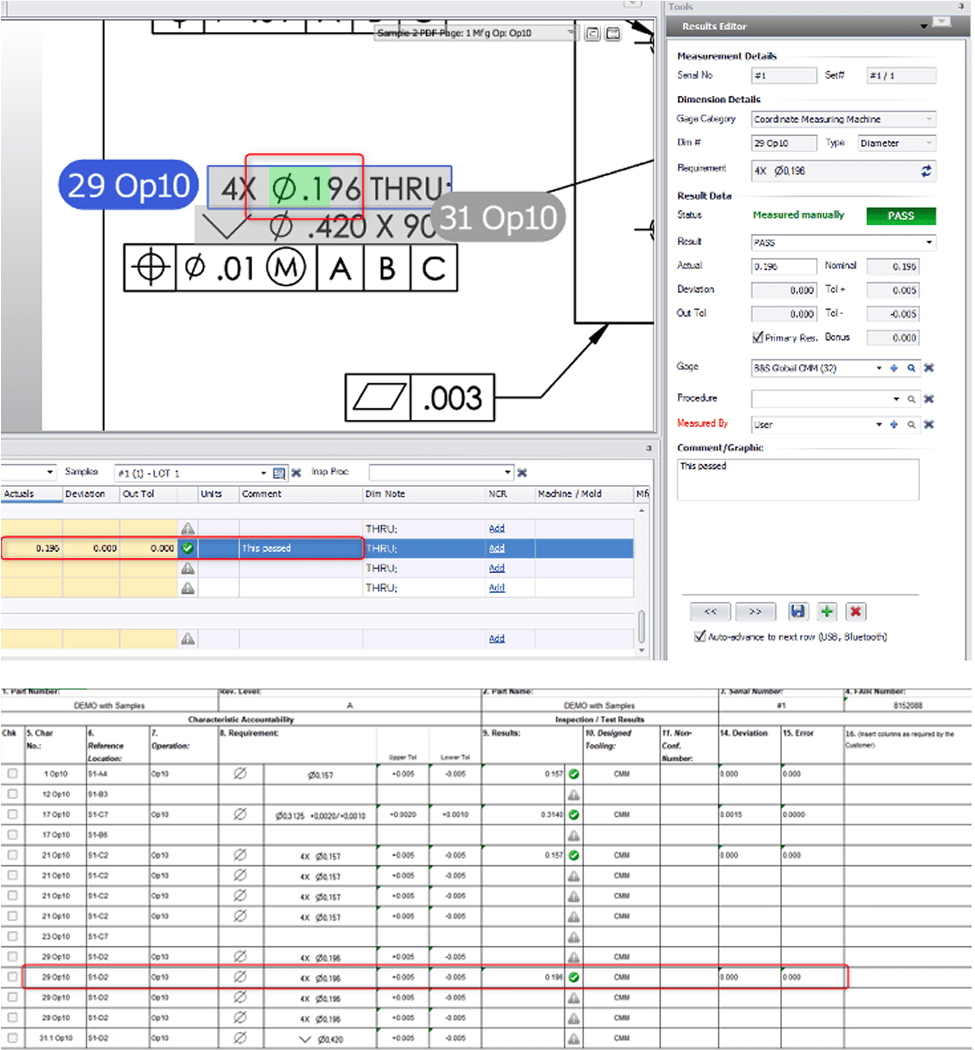

- Leverage IM Explorer and IM Express to input results directly from the shop floor, reducing delays and errors.

Root Cause Analysis

- Use linked data to trace defects back to their sources and implement corrective actions.

Trend Analytics

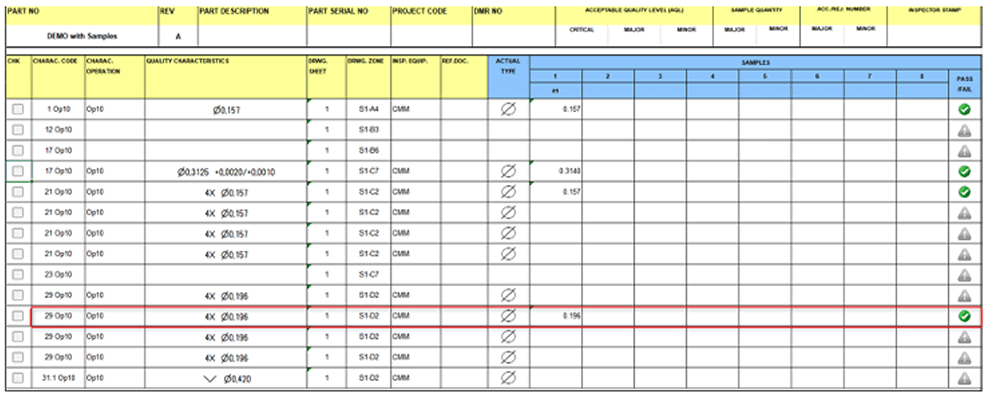

- Monitor defect patterns and NCR trends using dynamic dashboards to prevent recurrences.

Simplify Non-Conformance Processes

High QA’s defects management tools streamline every stage of NCR management:

- Identify Defects: Use built-in tools to capture detailed defect descriptions, attach drawings, and document evidence.

- Automate Notifications: Inform stakeholders and assign ownership of NCRs for immediate action.

- Resolve Efficiently: Track progress, document corrective actions, and close NCRs with a full audit trail.

- Monitor Trends: Use analytics to identify recurring issues and drive long-term improvements.

Addressing Defects for Long-Term Gains

Defect management tools in High QA go beyond basic tracking and include:

- Visual Documentation: Attach photos, drawings, and inspection data to NCR records for enhanced clarity.

- Collaborative Resolutions: Facilitate cross-functional collaboration to address non-conformance issues efficiently.

- Historical Data: Access NCRs and defect records to identify recurring issues and prevent future occurrences.

- Actionable Insights: Leverage defect trend reports to prioritize areas for improvement and strengthen process controls.

Discover More

Take control of your non-conformance processes with High QA’s robust NCR & Defects Management tools. Schedule a demo today to see how these features can enhance compliance, streamline workflows, and drive continuous improvement.