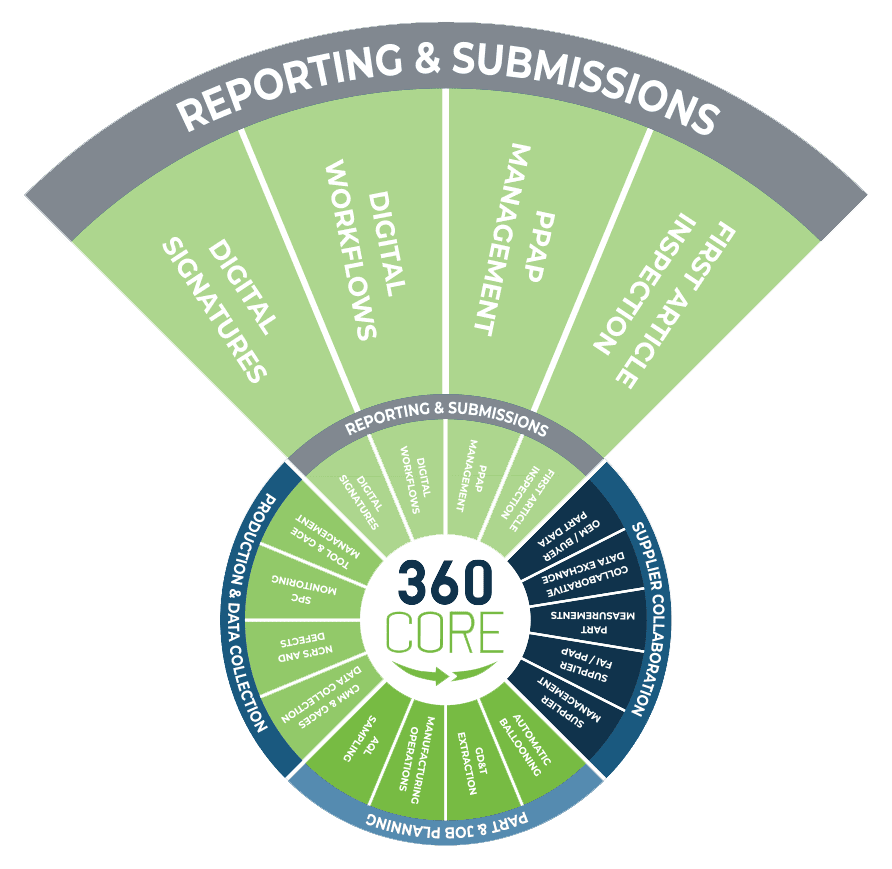

Reporting & Submissions

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

FIRST ARTICLE INSPECTION (FAI)

Streamline, automate and mistake-proof your first article inspection process

An AS9102 FAIR, or First Article Inspection Report (FAIR) validates that a product has been manufactured to the correct specification. Numerous large spreadsheets, detailed forms and compiled reports need to be gathered and often require 24+ hours of labor by quality engineers, manufacturers and other technical professionals to create. Processes may even need to change which can lead to missed deadlines.

360 CORE organizes and automates all aspects of an AS9102 first article inspection report to reduce the cost and time involved – and prevent errors along the way – helping companies streamline their manufacturing process.

PPAP

High QA supports the Production Part Approval Process (PPAP) by providing an integrated toolkit for managing and automating essential PPAP documents like Process Flows, PFMEA, and Control Plans. This centralized solution helps to ensure compliance, traceability, and efficiency for all your submission requirements, reducing the complexity of traditional PPAP workflows.

Overview

PPAP is a critical requirement for many manufacturers, especially in regulated industries like automotive and aerospace. High QA’s PPAP solution, part of the PQP (Production Quality Planning) module, simplifies the creation and management of essential PPAP documents while helping to ensure alignment with customer preferences and regulatory standards.

From generating ballooned drawings to building complete submission packages, High QA integrates tools for Process Flow Diagrams, PFMEA (Process Failure Modes and Effects Analysis), and Control Plans into a seamless workflow. By centralizing and automating document generation, manufacturers can streamline the approval process and focus on continuous improvement.

DIGITAL WORKFLOWS

High QA’s Digital Workflows enhance collaboration, streamline approvals, and help to ensure traceability throughout your quality management processes. Integrated into the PQP (Production Quality Planning) toolkit, Digital Workflows provide a centralized, automated approach to managing the lifecycle of quality documentation, including submission packages and compliance reports.

Overview

Managing quality documentation and approvals can be complex, with requirements varying for customers and industries. High QA’s Digital Workflows simplify this process by enabling teams to create, review, and approve inspection documents within a fully traceable system. From raw material certifications to PPAP submission packages, Digital Workflows help to ensure each document follows a structured path, complete with status tracking, user assignments, and compliance auditing.

High QA’s Digital Workflows integrate seamlessly into the PQP framework, supporting the entire lifecycle of

quality documents from creation to submission.

DIGITAL SIGNATURES

HighQA’s Digital Signatures bring a new level of security, traceability, and efficiency to quality management workflows. Integrated with the PQP (Production Quality Planning) module, this feature helps to ensure that all approvals are authenticated, logged, and fully traceable, meeting compliance standards such as AS9100, IATF 16949, and ISO 9001.

Overview

Digital Signatures provide an authenticated and auditable method for approving quality management documents, including First Article Inspections (FAI), PPAPs, and other critical records. These signatures help to ensure that every action taken within the workflow is secure, tamper-proof, and fully traceable.

High QA’s Digital Signature functionality integrates seamlessly into workflows, enabling teams to manage approvals efficiently while maintaining compliance with rigorous industry standards. From capturing electronic certificates to automating the signature process, High QA streamlines your reporting and approval workflows.