360 HUB:

Supplier Quality

Management for

Manufacturing OEMs

Trusted Partner with Industry 4.0 Solutions

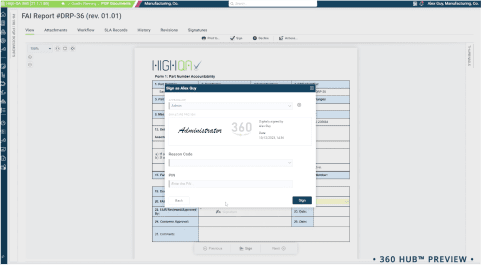

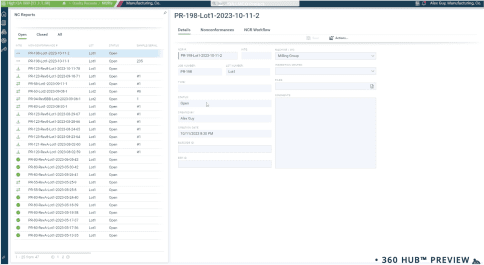

- Automate FAI/NCR processes with your suppliers

- Implement a quality based digital thread

- Eliminate incoming inspections

Manage Supplier Quality More Efficiently

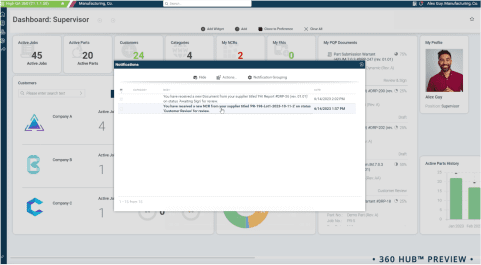

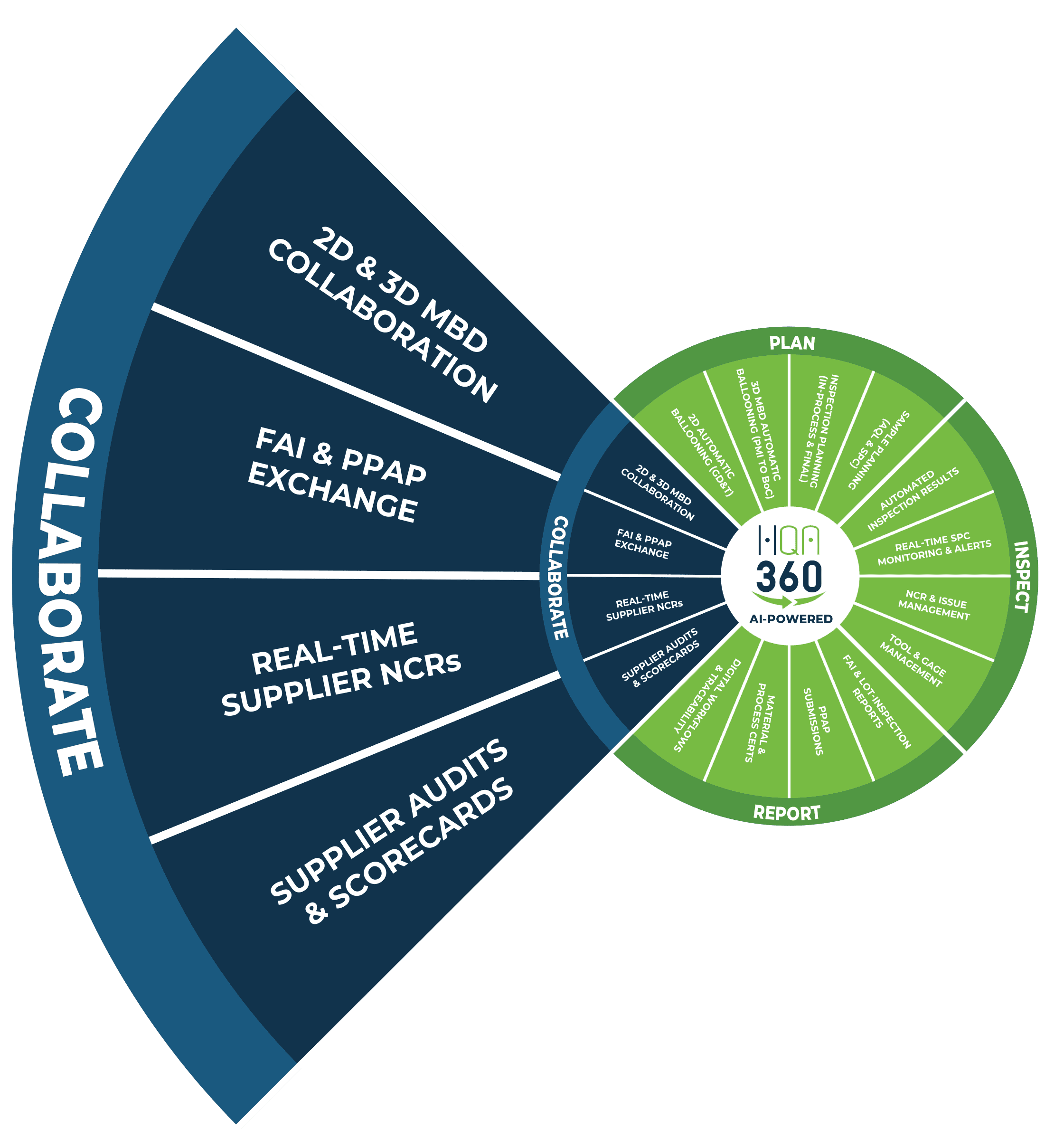

Collaborate with your suppliers using a supplier quality management (SQM) software solution that drives consistency and reduces errors. 360 HUB facilitates the sharing of real-time data so everyone is operating with the same up-to-date information which helps to minimize rework and production delays, as well as redundant data entry.

Key advantages of 360 HUB include improved supplier management, secure collaboration, standardized documentation, streamlined First Article Inspection (FAI) and Production Part Approval Process (PPAP) documents, smooth integration with Product Lifecycle Management (PLM) and Enterprise Resources Management (ERP) goals and processes. You can also benefit from seamless data flow involving RFQs, QA reports, prints, 3D models, and other essential documentation.

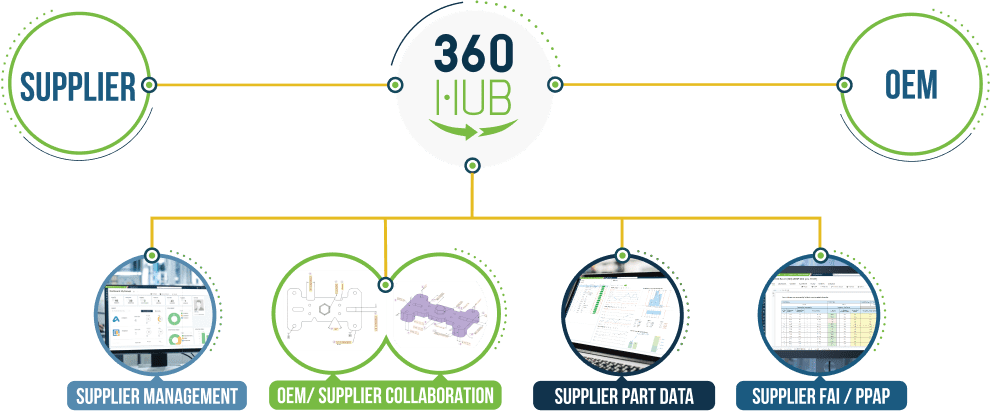

How it Works

Simply invite your suppliers to the HUB to create an environment where collaboration is frictionless and secure. Share documentation with partners in one convenient, easy-to-access location and stay aligned throughout the production process as if your partners were on the shop floor.

With 360 HUB, you and your suppliers will not just meet quality standards – you will exceed them!

Key Features & Benefits

Features

- OEM/Buyer Part Data

- Collaborative Data Exchange

- Part Measurement

- Supplier FAI/PPAP

- Supplier Management

Standardize

Standardize quality requirements for all suppliers and use a consistent document format so you can quickly find the information you need.

Collaborate

Collaborate with automated connectivity between buyers and suppliers to exchange data from quoting to FAI/PPAP report submission, eliminating paper trails, non-value-added work, errors, and delays.

Predict

Predict and maintain production schedules for manufacturing and receiving quality products so you can plan inspections and stabilize operations and delivery timelines.

Learn

Learn qualitative information about suppliers, compare and analyze quality data across multiple sources, and determine reliability and consistency, because successful supply chain partnerships involve far more than cost per part.

How HUB 360 Works

- Buyers invite Suppliers to the 360 HUB.

- 360 HUB allows the secure exchange and sharing of prints, models, and form

- 360 HUB allows for the standardization of submissions through the supply chain from RFQ to QA report.

- 360 HUB allows one use data, over time, to choose the right supplier, predict deliveries and quality, and respond accurately to RFQs

- 360 HUB enables productivity and collaboration with less friction throughout the supply chain.

The 360 HUB Difference

360 HUB allows users to obtain First Article Inspection (FAI), Part Production Approval Process (PPAP), and advanced ballooning data that allows you to manage a supply chain virtually and comprehensively. HUB is a valuable tool in today’s manufacturing environment because data suggests that delays, rework, and late shipments due to poor quality can add significant costs to the supply chain. 360 HUB helps to reduce or eliminate those costs and strengthen relationships between manufacturers and their customers.