HQA 360 Value Calculator

Calculate your potential savings when using High QA

to streamline manufacturing quality

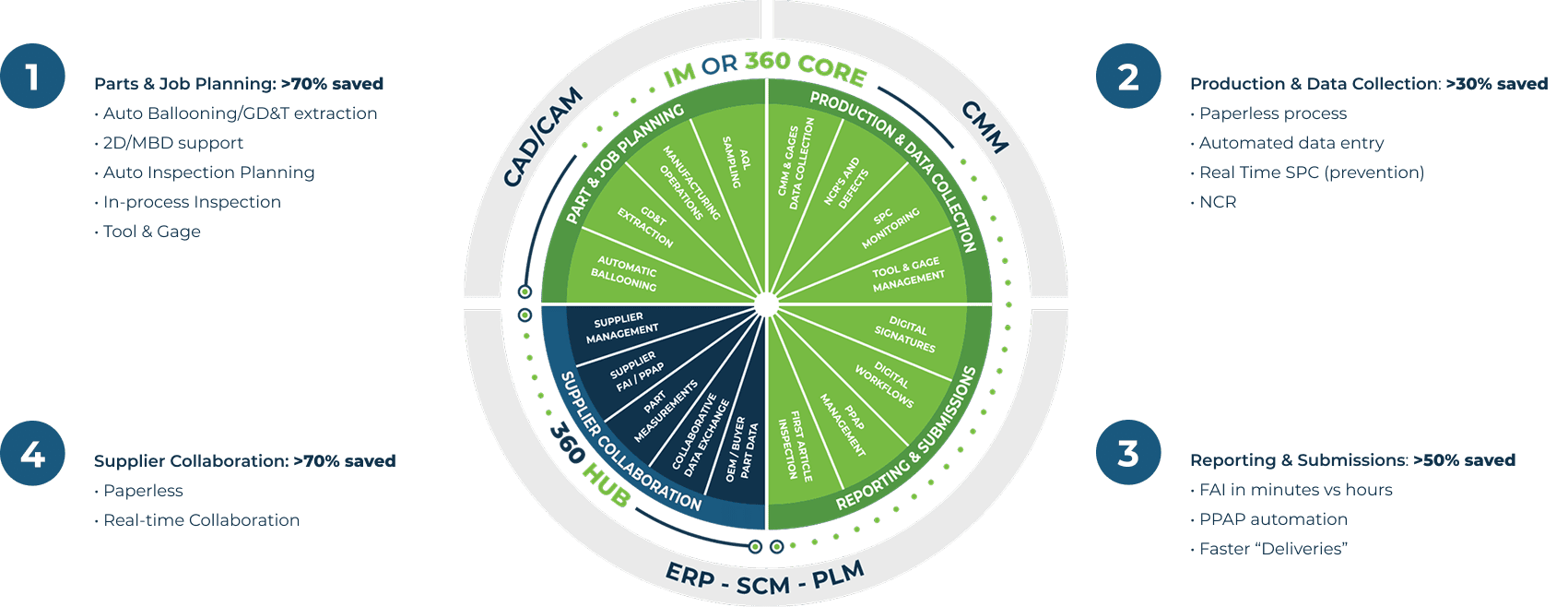

Thousands of quality professionals use the HQA 360 manufacturing quality platform every day to save time and money on their manufacturing quality processes.

You can too!

Proven Results

- Eliminates silos: Centralized database keeps departments aligned and reduces miscommunication.

- Prevents errors & cuts labor costs: Automates repetitive tasks so your team can do more with less.

- Boosts productivity by 50%: Improves collaboration and throughput across operations.

- Enhances customer satisfaction: Helps deliver parts on time, on budget, and on quality—every time.

- Ensures full traceability: Tracks every step from purchase order to final delivery.

HQA 360 Value Calculator

This value calculator is an easy way to show potential savings you could get from implementing HQA 360.

The results may surprise you.

Cost savings are preliminary estimates based on a limited data set and average savings multiples. They do not represent a guaranteed or legally binding cost savings.

For a more comprehensive assessment of how High QA can deliver cost savings, talk with one of our experts for a demo and learn more about the savings you can get by using the HQA 360 Platform.