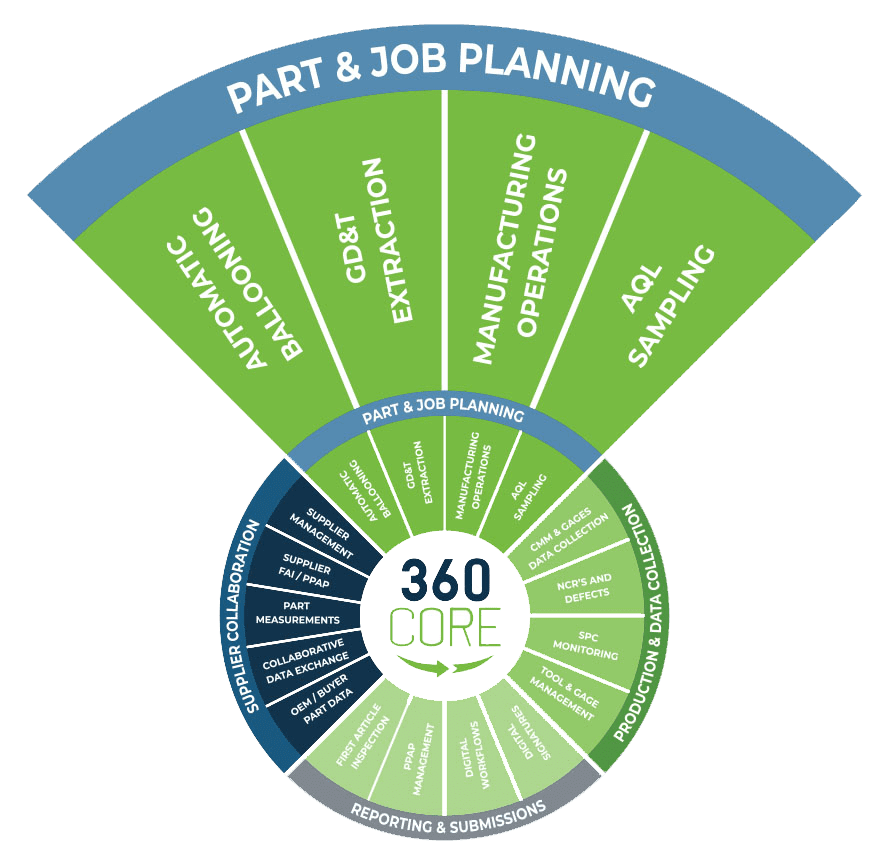

Part & Job Planning

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat. Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatur. Excepteur sint occaecat cupidatat non proident, sunt in culpa qui officia deserunt mollit anim id est laborum.

GD&T EXTRACTION

High QA’s GD&T Extraction feature ensures seamless transfer of Geometric Dimensioning and Tolerancing (GD&T) data from CAD models into actionable inspection plans. By automating this process, High QA minimizes manual errors, maintains compliance with the industry standards, and enhances efficiency. Integrated into Inspection Manager and 360 CORE, GD&T Extraction is a critical feature of High QA’s Quality Management Software.

Overview

Inspection planning is vital for translating design specifications into actionable quality requirements. High QA’s GD&T Extraction automates the interpretation of CAD data, ensuring compliance with APQP and AS9100 standards. This extracted data integrates seamlessly into the Bill of Characteristics (BoC), creating a centralized hub for managing quality workflows.

GD&T Editor

The GD&T Editor simplifies the definition and management of dimensional and tolerance requirements. With an intuitive Interface, it enables users to handle complex data efficiently and helps to ensure accuracy across projects.

AUTO-BALLOONING

How Do You Balloon Drawings and Extract GD&T/PMI Data?

High QA’s ballooning software is a key part of the quality management process. One-click auto-ballooning using optical character recognition (OCR) takes out the manual process for ballooning and GD&T extraction saving you time and money. You really can automatically balloon drawings for your quality process.

Manual Process

- Cumbersome

- Inaccurate

- Time Consuming

- Inconsistent

Hundreds of balloons need to be hand-drawn. Dimensions and notes need to be manually entered into a spreadsheet. Interpretation and data entry errors lead to inaccuracies in quality.

Automated Process

- Simple

- Repeatable

- Accurate

- Fast

Inspection Manager is an efficient, automated digitized solution to automate ballooning drawings and extracting GD&T/PMI data into a useable dynamic bill of characteristics.

See how ballooning and GD&T/PMI data extraction should be done.

3D-MBD INTEGRATION

Inspection Planning is Greatly Enhanced with 3D MBD

In recent years, more and more design and manufacturing companies are embracing solid and surface modeling techniques. However, 3D models often lack GD&T (geometric dimensioning and tolerancing) information that is necessary for the quality assurance organization.

The main problem with the typical CAD model is that it requires a separate drawing sheet to determine datum structure, key characteristics, and tolerancing to create an inspection plan. With 3D MBD, all pertinent product information and inspection planning data is included in one model, there is no longer a need for a 2D drawing.

360 CORE enables you to use 3D MBD files directly into an automated, streamlined manufacturing quality process – just like using a 2D drawing.

MANUFACTURING OPERATIONS

High QA’s Manufacturing Operations tool simplifies inspection planning by breaking down your production lifecycle into manageable stages. Integrated within Inspection Manager, this feature enables you to define inspection requirements for each manufacturing step, from roughing to finishing, ensuring alignment with PpK Process standards and improving compliance during supplier audits.

Overview

Plan inspection requirements at every stage of production with Manufacturing Operations. This tool allows users to create tailored workflows for inspection steps like drilling, milling, and plating while connecting them to High QA’s 360 CORE system. Whether working with default settings or building custom operations, manufacturers can streamline workflows and ensure quality across every step of the production lifecycle.

AQL SAMPLING

High QA’s AQL Sampling tool simplifies the process of setting and managing Acceptance Quality Limit (AQL) standards for your manufacturing processes. Integrated into Inspection Manager, this feature empowers teams to establish clear sampling rules, ensuring product quality and compliance at every production stage.

Overview

AQL Sampling is an essential part of maintaining product quality. High QA’s tools make it easy to define sampling criteria for dimensions and inspection characteristics within the Bill of Characteristics (BoC). With automated sampling rules and customizable settings, manufacturers can ensure consistent results and adherence to quality standards. This feature integrates seamlessly with 360 CORE, allowing for streamlined workflows that reduce risk and enhance process control.