The High QA quality manufacturing suite enables the world’s strongest companies to manage quality, increase efficiency, meet customer requirements, reduce risk and achieve operational excellence.

Improve the Way You Manage Quality in Manufacturing

with HQA360

Explore Our Manufacturing Quality Solutions

Quality Manufacturing Suite

| Features | Job Shop | Factory | Factory Pro | Enterprise |

|---|---|---|---|---|

| Database Driven |  |

|

|

|

| One-Click Ballooning and GD&T Extraction |                                 |

|

|

|

| Inspection Plan Report/File |                                 |

|

|

|

| Import/Enter Inspection Data |                                 |

|

|

|

| Report Designer and Templates for FAI, PPAP and others |                                 |

|

|

|

| In-Process Manufacturing and Inspection | - |                                 |

|

|

| Automatically Import Inspection Machine Data (AMDI) | opt | opt |                                 |

|

| Statistics Process Control (SPC) | opt | opt |                                 |

|

| Browser/Tablet Applications for Data Collection | - | opt |                                 |

|

| Tabulated Drawing/Parametric Design | opt | opt | opt |                                 |

| PQP (Production Quality Planning) – APQP/PPAP Solution | - | opt | opt |                                 |

| API | opt | opt | opt | opt |

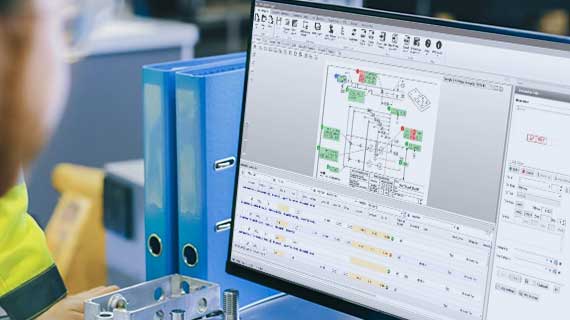

HQA360 Software Solution

Managing your quality process doesn’t have to be difficult. The High QA quality manufacturing suite makes it simple.

A fully integrated quality management software for manufacturing, HQA360, previously known as Inspection Manager, brings flexibility, efficiency, and productivity to your quality process.

Comprehensive automation tools reduce costs, prevent human interpretation errors, improve delivery time and part quality ensuring your customers are always confident in your products.

From ballooning and part planning to inspection data collection and reporting, HQA360 has the quality manufacturing solutions (QMS) you have always wanted.

Ballooning

Ballooning a drawing is a key part of the quality process. With one-click, a drawing is auto-ballooned using optical character recognition (OCR) that takes out the manual process of ballooning and GD&T extraction saving you time and money.

FAI

HQA360 organizes and automates all aspects of an AS9102 first article inspection (FAI) report to reduce the cost and time involved – and prevent errors along the way – helping you streamline your manufacturing quality process.

APQP / PPAP

HQA360 PQP is a powerful non-Excel based solution helping you to fulfill APQP / PPAP process requirements and revolutionizes the way product submission packages are composed, generated, tracked, signed, and stored.

SPC

HQA360 delivers SPC tools to collect data in a centralized database and analyze real-time run charts, X-bar and R, stability (Cp, Pp) and capability (Cpk, Ppk) information to improve process performance, manufacturing quality and part consistency.

3D MBD

Traditionally, quality processes have relied on 2D drawings in the ballooning, planning and inspection process. Now, High QA has made it simple to incorporate 3D models (3D MBD) in your quality process.

PFMEA

Anticipate and prevent potential manufacturing quality issues. HQA360 provides an easy-to-use, straight-forward, single integrated tool to generate consistent, standardized PFMEAs.