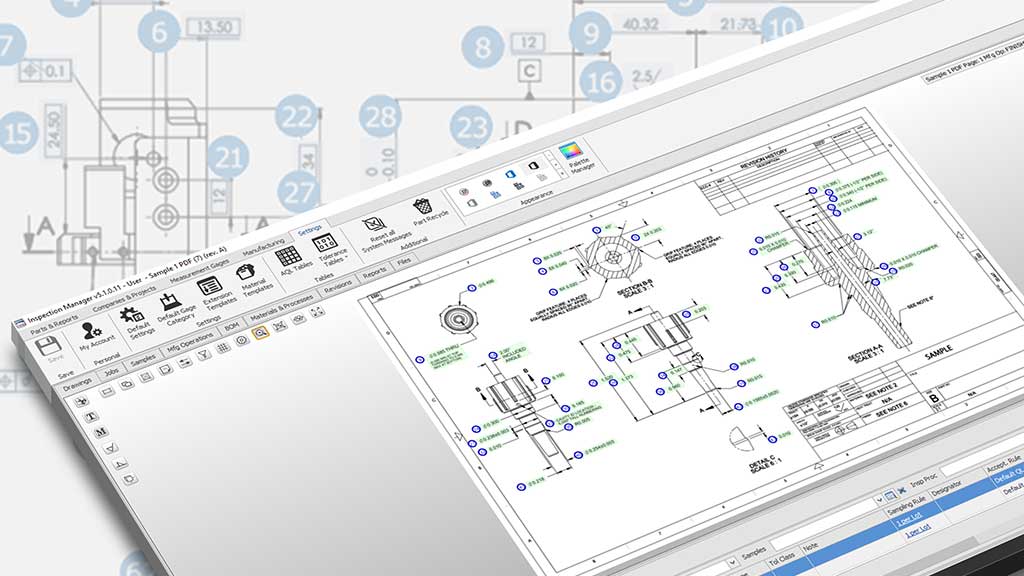

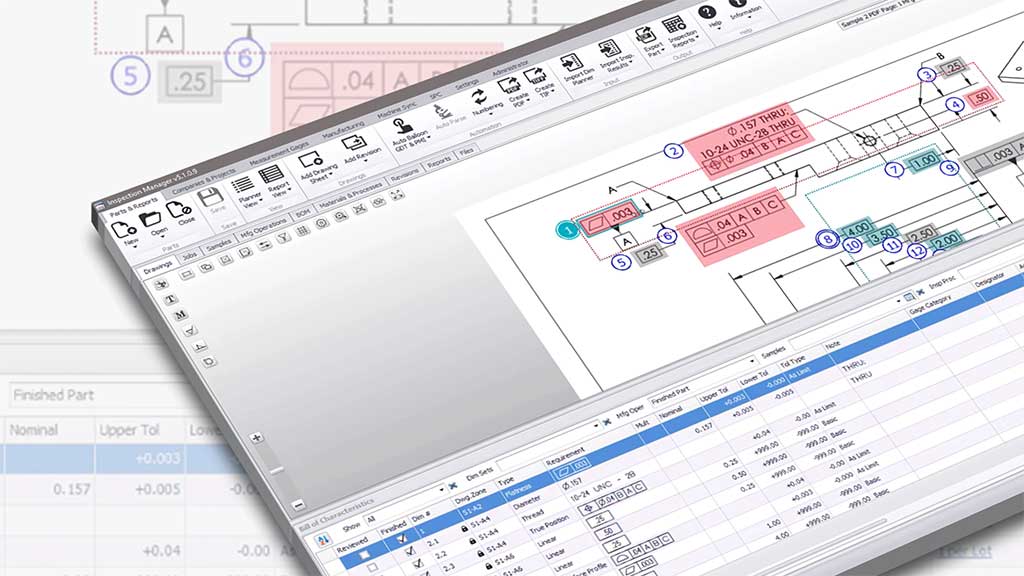

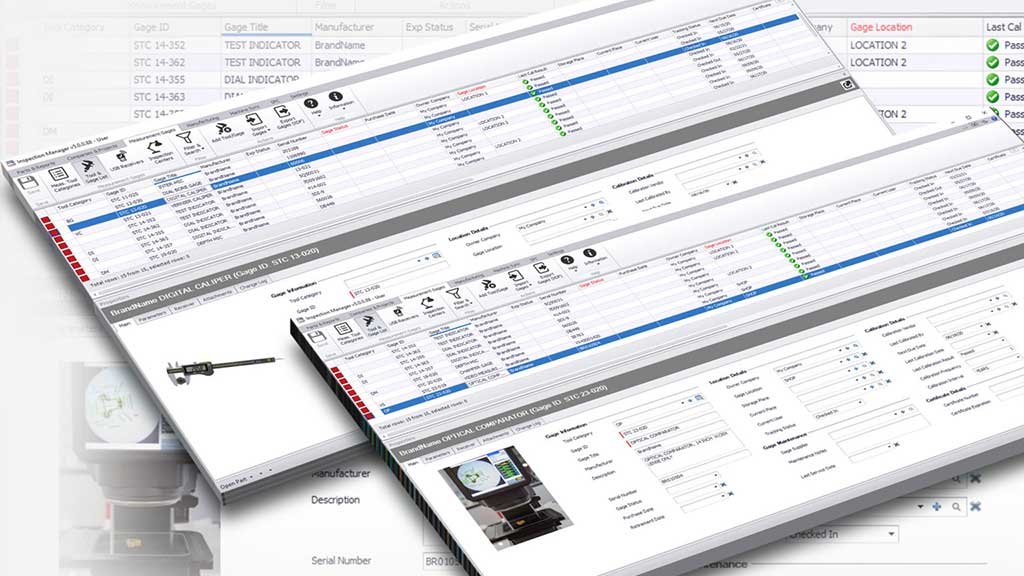

Tool & Gage management is a critical element enabling trusted inspection results either within your facility or from an outside supplier. It allows automated inspection tool category assignments based on the feature recognition from the 2D drawings.

Management and tracking of inventories, storage locations, and most current users reduces wasteful time spent searching for tools and reports. All information is readily available in one centralized database in one manufacturing quality management software.

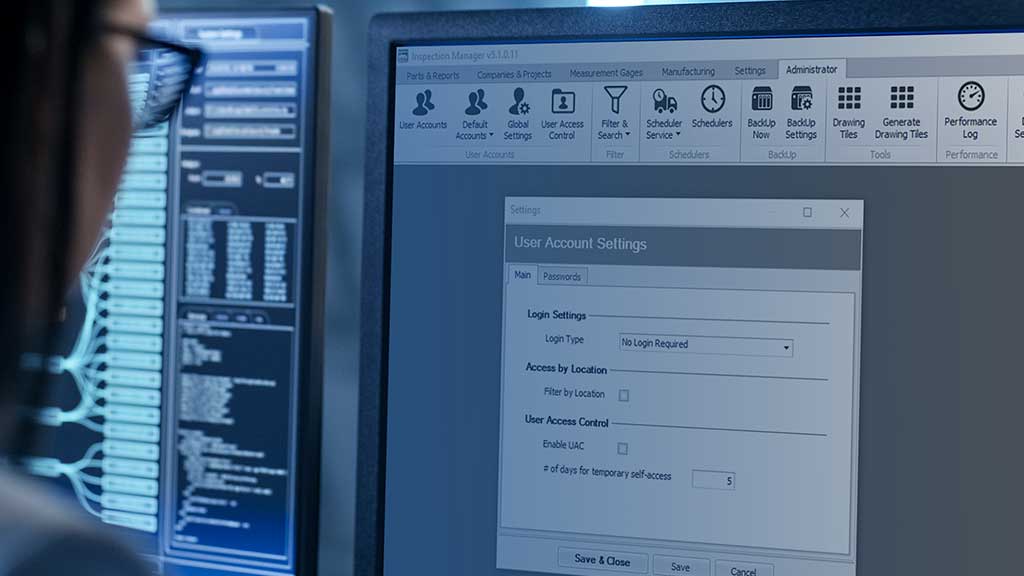

You can quickly identify a detailed usage history for each tool or gage and can filter usage by part, job, inspector, and date range to prevent inspection results from out of calibration tools.

Bluetooth, wireless, and wired inspection tools are supported seamlessly and do not require any external hardware or communication protocols.

Scheduled calibration time alerts are sent well in advance so that important calibration duties are always maintained.